Navigation

At-Bit Inclination Allows Consistent Curve Doglegs for Fiber Optic Casing

APPLICATION

/ Geosteering

/ Curve Dogleg Consistency

/ Fiber-Optic Production Casing

/ Multi Well/Pad Drilling

TECHNOLOGY

/ Directional Drilling Services

/ TiTAN22 6.60” 4/5 7.0 Performance Drilling Motor

/ Logging While Drilling (LWD)

/ Smart Motor Mandrel-Integrated Azimuthal Gamma Ray/Inclination sensor

/ Measurement While Drilling (MWD)

/ Falcon MP MWD

LOCATION

/ South Texas, Eagleford Shale

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

An operator in South Texas planned to run fiber-optic cables to monitor production during a casing operation.

Keeping doglegs consistent was vital to ensure the fiber-optic cables were not damaged. For instance, the production casing tripped to the bottom. Their geosteering program also called for landing low in their target window at the bottom of the reservoir. For example, to not puncture the formation directly below.

SCIENTIFIC SOLUTION

Scientific Drilling International (SDI) provided at-bit inclination sensors in the TiTAN22 Smart Motor package. For instance, real-time monitoring of motor dogleg output. SDI’s BitSub electronics power the TiTAN22 package. Therefore, this new instrumented motor design integrates the at-bit electronics of the BitSub inside the motor mandrel. For example, allowing for higher allowable motor bends.

To drill the planned 7° /100 curve section, a high-speed 4/5 7.0 power section with a 2.12° motor bend was selected. Scientific Drilling’s Falcon MWD system helped pulse the at-bit gamma ray and inclination to the surface. This system utilizes a licensed Wi-Sci EM short-hop technology to establish the bi-directional communication between the MWD tool and the at-bit electronics. The proven short-hop technology works in water- and oil-based mud systems. Above all, it is compatible with many mud motor power sections.

CUSTOMER VALUE

With its at-bit inclination measurements, Scientific Drilling’s Smart Motor allowed the operator to monitor motor yields proactively. For instance, the motor ensured they stayed on track and put large doglegs in the curve section.

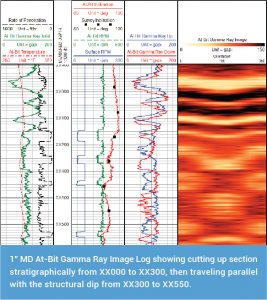

Keeping the curve doglegs under 10°/100 allowed smooth casing running operations and prevented damage to the fiber optic cables. Doglegs averaged 6.79°/100 with a maximum of 8.31°/100. The curves landed on target, and the assembly drilled to the planned coring point halfway through the lateral. After the coring rans finished, a new instrumented Smart Motor with a 1.50° bend picks up. Therefore, it fulfilled the use of absolute depths. Real-time azimuthal gamma rays at the bit allowed precise geosteering and well placement. Above all, even with bottom-hole temperatures reaching as high as 318° F (159° C).

YOU MAY ALSO BE INTERESTED IN

Real-Time Pore Pressure Prediction Using ULT’s Sonic Measurement