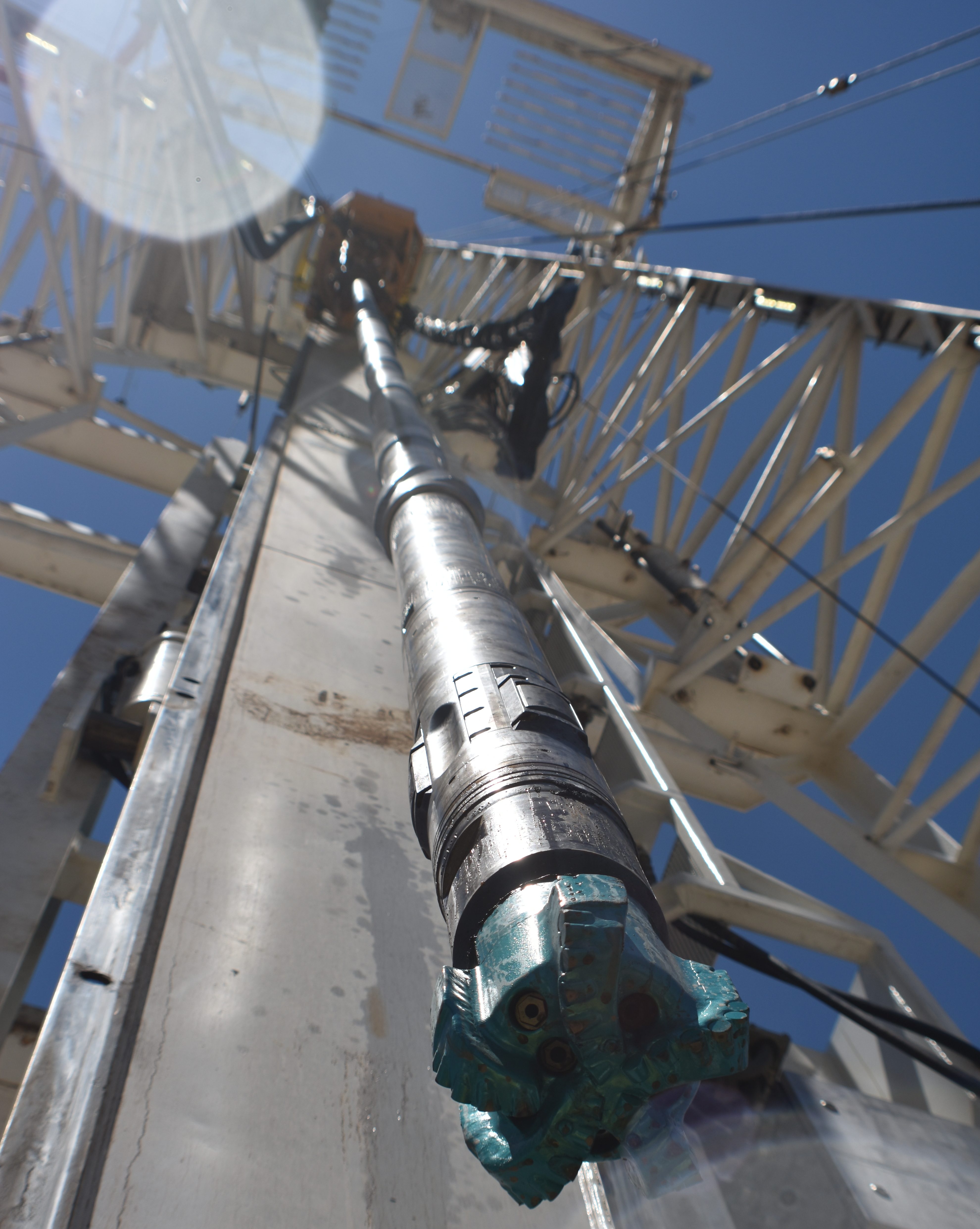

HALO

High-Performance Rotary Steerable System for Unconventional Challenges

Designed to overcome North American land challenges, Scientific Drilling’s HALO high-performance rotary steerable system solves reliability and economic challenges, while yielding more efficient, smoother wellbores.

Built to complete vertical, curve and lateral sections in one run, it helps avoid costly trips and improves ROP. Operating at a maximum bit speed up to 350 RPM, the HALO RSS maximizes performance and reduces rig time.

The system maximizes wellbore exposure in the target zone by drilling curve sections with build rates up to 15°/100 ft. Its 3D advanced directional control system delivers unparalleled lateral placement.

Consisting of an integrated steering unit and MWD survey package, it is fully assembled and qualified prior to delivery to the rig site. This minimizes BHA assembly time and mitigates associated HSE risks.

For more information on improving your drilling efficiency-while staying on target-contact your Scientific Drilling sales representative.