Navigation

Multilateral Well Intersection

APPLICATION

Horizontal to Horizontal Intersection,

Precise Relative Placement,

Multilateral,

Geothermal,

HDD

TECHNOLOGY

SDl’s Lodestone: Long-Distance

At-Bit While-Drilling Active

Magnetic Ranging System

LOCATION

Alberta, Canada

CUSTOMER CHALLENGE

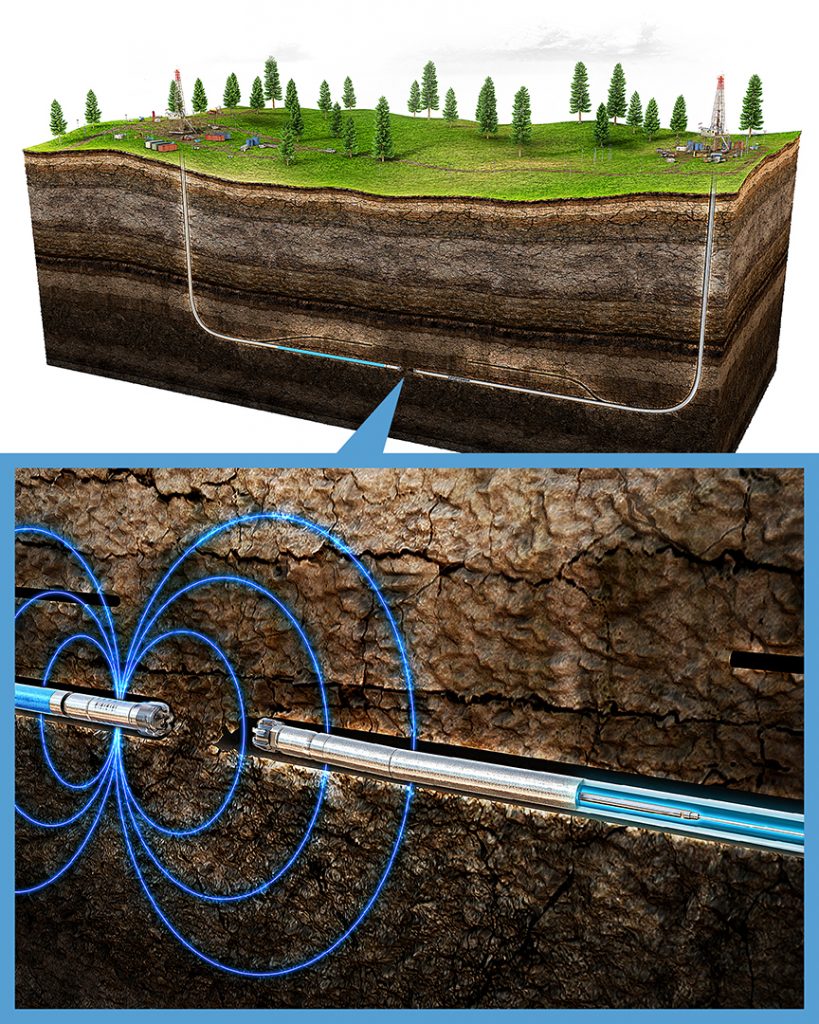

The client needed accurate downhole navigation to overcome MWD positional uncertainty, provide an exact relative position between wellbores, and connect two multilateral wells spudded 2350m (7700ft) apart at 2400m (7870ft) vertical depth.

SCIENTIFIC SOLUTION

Each well consisted of two lateral wellbores. The average length of each well was 3440m (11280ft) with 2350m (7700ft) lateral separation between the target well and intercept well surface locations. Meanwhile, causing a significant MWD positional uncertainty at the planned intersection points. Because of this uncertainty, the wells drill towards each other to align the opposing laterals axially as much as possible. For instance, this uses conventional MWD systems until a predetermined separation distance remains between the target and intercept wellbores.

When this set distance between the first arranges of opposing lateral wellbores was reached, the Scientific Drilling International Lodestone magnetic ranging system deployed to pinpoint the intercept well location concerning the target well. Therefore, resetting the MWD uncertainty and correcting the good intercept plan for the first intersection. The system’s magnetic field source includes in the intercept well BHA right above the bit. Therefore, the system’s receiver was pumped down to the bottom of the target well on the wireline through the drill pipe. In conclusion, a similar approach follows during the second intersection.

CUSTOMER VALUE

Utilizing the well intersection service and Lodestone technology from Scientific Drilling, the client connected all wellbores safely and completed the World’s first-of-its-kind multilateral horizontal drilling intersection.