Navigation

Major Geothermal Power Plant Casing Inspection Monitoring

APPLICATION

/ Wellbore Integrity

TECHNOLOGY

LOCATION

/ Asia Pacific

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

The operator of a global top 10 geothermal energy plant (by installed capacity) had a long-term requirement to monitor the condition of its cased wells where temperatures can exceed 300°C.

To minimize cost and potential damage to the reservoir, the operator favored a solution that would negate the need to quench the well and deploy conventional logging instruments.

Some of the operations would be performed on a workover rig, making prompt data turnaround necessary to help plan subsequent remedial interventions.

SCIENTIFIC SOLUTION

Scientific Drilling was selected as the preferred supplier, thanks to its technology and experienced personnel. With a temperature rating of 315°C and a measurement range of 5.5″ to 14.5″, the Vulcan™ MFT-40 multi-finger caliper was the ideal solution.

The Vulcan™ MFT-40 was deployed 25 times in one year, achieving a run success rate of 92%. With a sample rate of 0.02s, data was acquired at a vertical resolution of 0.12″, providing highly detailed insight into the internal wellbore geometry.

A log analyst was on standby for every run, providing a quick look at the data within ~2 hours and a comprehensive report within 24 hours.

CUSTOMER VALUE

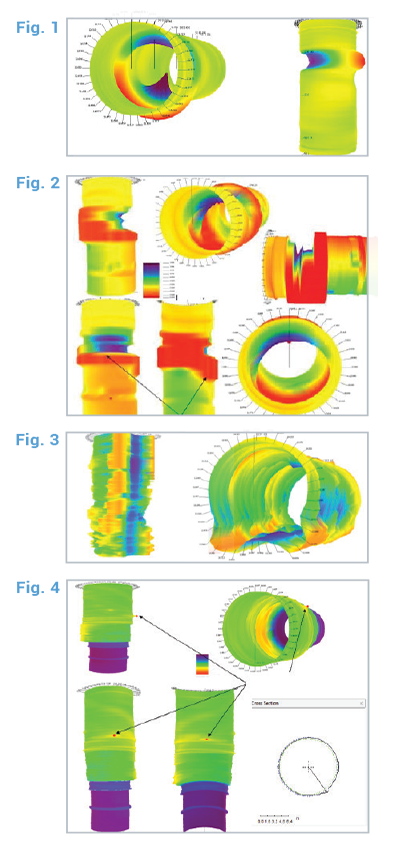

The operator gained a thorough understanding of the condition of its wellbores, enabling it to plan remedial interventions with precision. Previously unknown issues revealed by the Vulcan MFT-40 included severe buckling (figures 1 & 2), an inadvertent casing exit (figure 3), and holes (figure 4).

For more information on the leading caliper technology for high-temperature wellbore inspection requirements, contact your Scientific Drilling sales representative: https://scientificdrilling.com/contact/

YOU MAY ALSO BE INTERESTED IN

Scientific Drilling’s Cased Hole Services technology once again shows its reliability by assisting a client in identifying anomalies and evaluating well integrity.