Navigation

Replacement Lateral Drilled Using Magnetic Ranging

APPLICATION

/ Production Recovery

/ Collision Avoidance

/ Well Twinning

TECHNOLOGY

/ Passive Magnetic Ranging

/ MagTraC

/ Continuous Btotal

/ Measurement While Drilling

/ Falcon MP MWD

/ Logging While Drilling

/ Smart Motor

/ Natural Gamma Ray

& Inclination (SCI-GAIN™)

LOCATION

Leduc-Woodbend Oilfield | Alberta, Canada

DOWNLOAD CASE HISTORY

/ PDF File

CLIENT CHALLENGE

The client was unable to produce from a lateral wellbore in a highly productive reservoir zone due to complications encountered while running the liner. To regain access, they planned to drill a sidetrack that would closely twin the existing wellbore.

This approach introduced several challenges: the sidetrack would need to remain close enough to avoid offset vertical wells and prevent crossing hard lines, while still maintaining safe separation to avoid collision with the original well.

Adding to the complexity, the existing well was drilled nearly due west—a direction that creates the largest positional uncertainty for magnetic surveys and required heightened precision in trajectory planning.

SCIENTIFIC SOLUTION

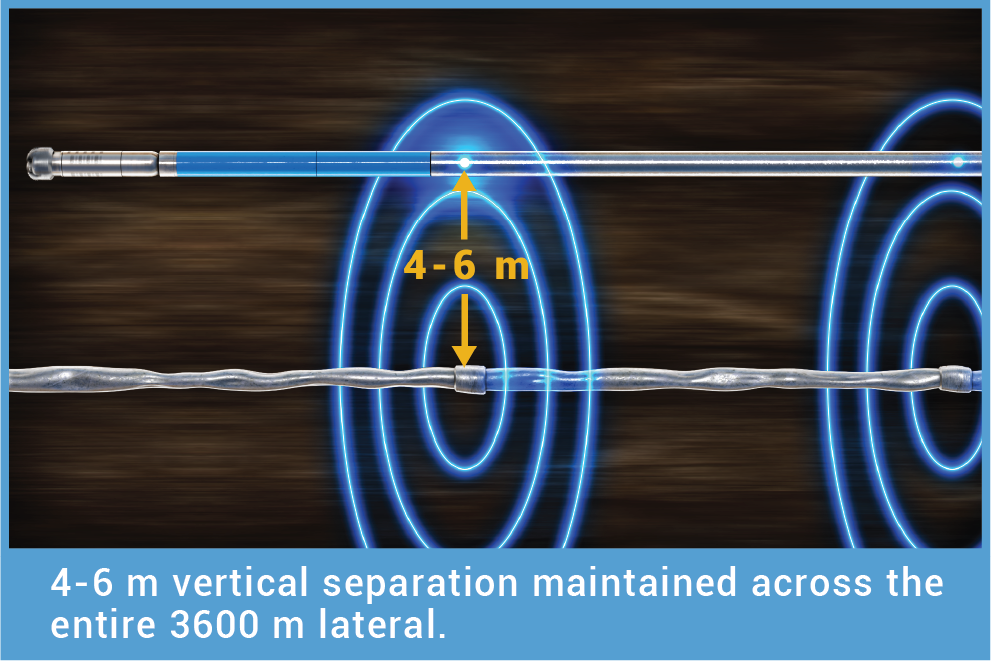

Before drilling, Scientific Drilling International (SDI) determined a twinning window of 4–6 m vertical separation and 3 m left/right separation from the existing well. This spacing allowed the sidetrack to stay close enough to detect magnetic interference without compromising MWD survey azimuths, while also mitigating anti-collision and boundary-crossing risks.

SDI’s Falcon MWD system was used to accurately orient the whipstock. After milling out, SDI’s Smart Motor provided real-time near-bit inclination data to land the sidetrack directly above the existing well at approximately 1,580 m TVD.

Throughout the 3,600 m lateral twinning section, SDI’s MagTraC™ passive magnetic ranging delivered definitive relative position measurements between the sidetrack and existing well. These results guided ahead-of-bit steering decisions to ensure the well remained within the defined twinning window. Continuous Btotal™ logging of magnetic interference further supported proximity monitoring, allowing longer drilled intervals between ranging runs.

CLIENT VALUE

SDI’s technology and expertise enabled the client to access the productive reservoir zone without the added cost of drilling a new well from surface, ensuring minimal disruption to their ongoing operations while preserving the potential production from the original well.

MagTraC™ passive magnetic ranging delivered the precise positional clarity needed to safely drill the twin wellbore, avoiding collisions with nearby offset wells and preventing hard boundary crossings. Continuous Btotal™ measurements further enhanced efficiency by reducing the number of required ranging runs, streamlining the drilling process and supporting a safe, consistent execution

CLIENT TESTIMONIAL

“I would like to extend a huge thank you to everyone involved in this well. Your communication, planning, and execution were flawless; truly professional on all levels. It has been a pleasure watching you guys work. Based on our success, this technology will be considered

on future projects without a doubt.”

– Client Drilling Engineer

YOU MAY ALSO BE INTERESTED IN

High-Angle Memory Gyro Survey Success In Magnetic Interference Zone