Navigation

Vulcan™ MFT-40 Discovers Inadvertent Sidetrack

APPLICATION

/ Geothermal

/ Well Integrity

TECHNOLOGY

LOCATION

Asia Pacific

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

After milling out 10-3/4″ scab liner, the geothermal operator wanted to assess the condition of 13-3/8” casing for anomalies such as metal loss, buckling and other forms of deformation using a multifinger caliper. The threat of high downhole temperatures limited the availability fit-for-purpose logging tools.

SCIENTIFIC SOLUTION

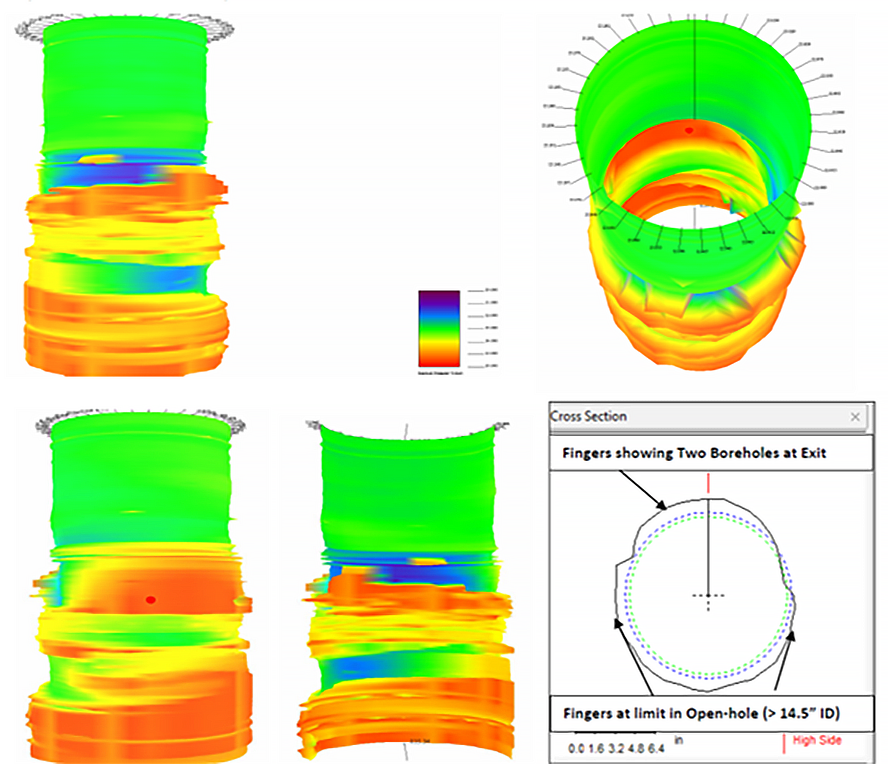

Scientific Drilling’s Vulcan™ MFT-40 multi-finger geothermal caliper was chosen to survey the well and confirm the status of the 13-3/8″ casing. Upon processing the caliper data, the log analyst soon realized a major anomaly had been detected by the caliper. The cross-sectional diagram shows that two boreholes were detected, one cased hole and the other open hole. This signified an inadvertent sidetrack.

The 3D images clearly depict the contrast between the cased hole and the open hole as the caliper fingers reach their measurement limit of 14.5″.

CUSTOMER VALUE

By utilizing SDI’s Vulcan™ MFT-40 caliper, the operator gained crucial insight into the status of its well. With this information, a tailored remedial program was implemented to regain well integrity.

YOU MAY ALSO BE INTERESTED IN

High-Temperature Geothermal Casing Integrity Inspection