Navigation

Chasing Sub-Seismic Sandstone Reservoirs with At-Bit Azimuthal Gamma Ray and Inclination

APPLICATION

/ Geosteering

/ Formation Evaluation

/ Wellbore Imaging

TECHNOLOGY

/ Logging While Drilling (LWD)

/ BitSub At-Bit Azimuthal Gamma Ray/Inclination sensor

/ Measurement While Drilling (MWD)

/ Falcon Electromagnetic (EM) MWD

LOCATION

/ Alberta Province, Canada

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

An operator drilling in Southern Alberta identified an oil-rich target formation and planned a series of horizontal wells for their 2022 drilling campaign.

Offset vertical well logs revealed the sandstone formation less than 3m thick. Furthermore, this ultimately leads to difficulties imaging the formation through traditional vibration data purchasing methods. Not only were geologic structure variations expected in the formation dip along the 2000m of vertical section, but also the possibility of lateral stratigraphic variability in formation thickness. The goal was not hydraulically stimulating the traditional reservoir—the lateral wellbore exposure to the target formation directly correlated with the production efficiency.

SCIENTIFIC SOLUTION

The well’s production efficiency and economic success were heavily related to the percentage of geosteering target accuracy. Scientific Drilling’s advanced LWD sensors were critical in providing accurate and reliable data to the onsite geologists for log correlation purposes.

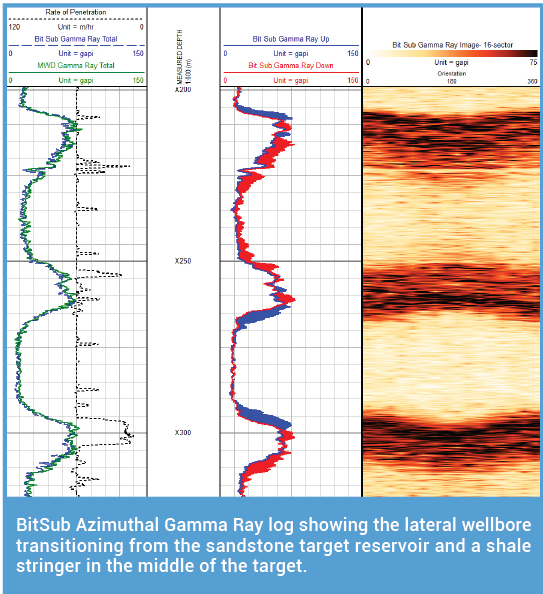

The operator could determine which direction to steer their lateral based on the azimuthal gamma ray and continuous inclination at the bottom of the mud motor—for instance, Scientific Drilling’s BitSub technology, an industry-leading LWD measurement sub at the bit.

Meanwhile, transmitting the at-bit data to the Falcon EM MWD system via Short Hop, the mud motor power section, was used to maximize drilling performance. For instance, optimal data density for real-time Total Gamma Ray, Up/Down Gamma Ray, Continuous at-bit inclination, Tri-axial vibration, and static borehole surveys achieved up to 60m/hr ROPs.

CUSTOMER VALUE

Scientific Drilling’s BitSub tool enabled the execution of proactive geosteering methods for the project. BitSub’s at-bit inclination reduced slide times and minimized unexpected doglegs in the lateral. Its azimuthal gamma ray measurements provided the geosteering team with easily identifiable indicators of the well. For example, cutting up or down stratigraphically allows course corrections to produce confidently and quickly. Because the BitSub’s placement is below the mud motor and above the bit, the tool is constantly rotating. Therefore, there is no need to go back and re-log azimuthal data over slide intervals. The Short Hop technology between the BitSub and MWD tool worked flawlessly in the oil-based mud system.

YOU MAY ALSO BE INTERESTED IN

At-Bit Inclination Allows Consistent Curve Doglegs for Fiber Optic Casing