Navigation

Fracture Salvage Well Drilled with Magnetic Ranging

APPLICATION

/ Frac Salvage

/ Twinning

/ Collision Avoidance

TECHNOLOGY

/ Lodestone Active Ranging System

/ Falcon MP MWD

LOCATION

West Texas, Permian Basin

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

The client had casing failure in a newly drilled and fracked horizontal well that prevented re-entry into the horizontal. The well had yet to be produced from and the formation was charged from the fracking process.

The client wanted to twin the existing well to salvage production while staying within the existing fracture radius. This presented several challenges:

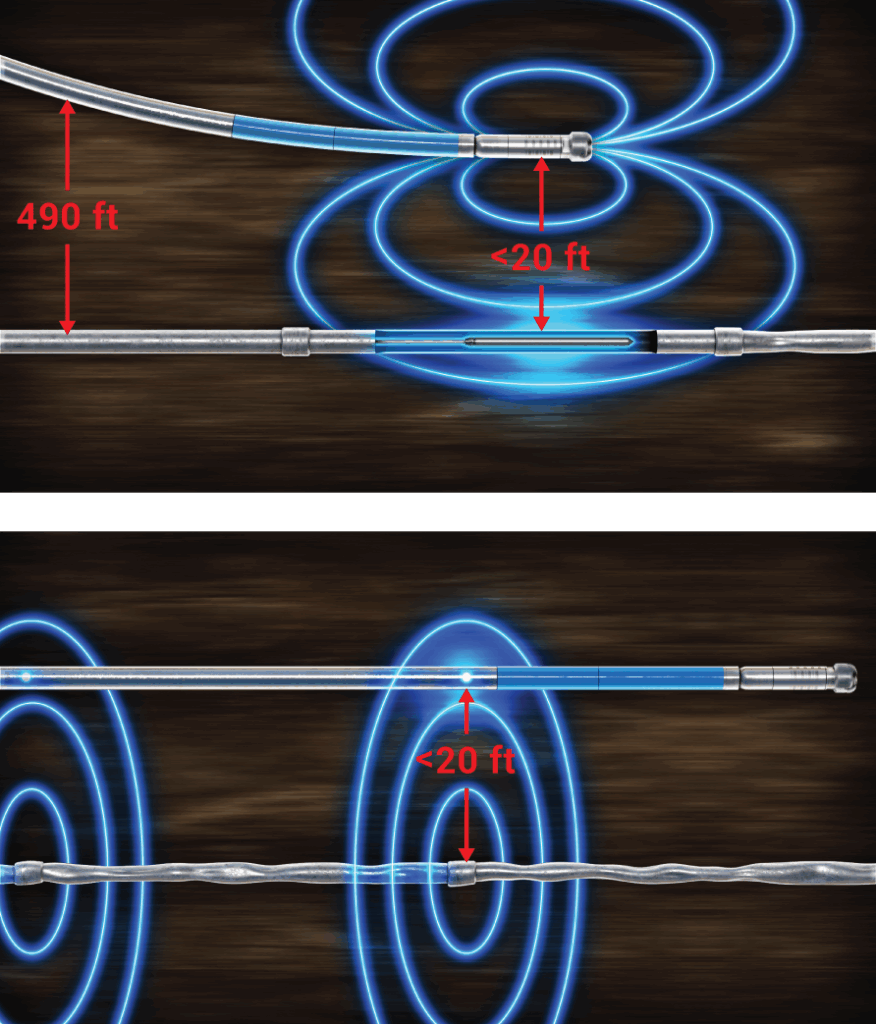

1. The well had to be drilled from an offset location 490ft away. Magnetic ranging would be required to locate the existing well and get within the desired proximity prior to landing.

2. Potential for variable casing signal strength in the existing well due to casing damage.

3. The twin well needed to maintain 10-20ft proximity to the existing well, which had a highly tortuous trajectory across the lateral section.

SCIENTIFIC SOLUTION

Both passive and active magnetic ranging were utilized to locate and twin the existing well. Lodestone active magnetic ranging was used to locate the existing well and establish alignment prior to landing the well. Across the lateral section, MagTraC passive magnetic ranging was used to provide the definitive relative position of the existing well to the twin well. During this section, Continuous BTotal logging of the magnetic interference was used as a qualitative measure of proximity.

There were two phases to the ranging operations: Locate and Twinning.

Locate phase: The Lodestone sensor was placed in the existing well, above the point of casing failure. A bit sub containing rare earth magnets was placed in the drilling BHA, enabling the produced alternating field to be measured by the sensor in the existing well, thereby providing a distance and direction from the drill bit in the twin well to the position of the sensor in the existing well.

Twin phase: The local magnetic field was continuously logged by SDI’s MWD sensor, measuring the magnetic anomalies caused by the existing well casing. Analysis of the Continuous Btotal log yielded proximity data and enabled the precise intervals for passive ranging data collection to be identified. The ranging results facilitated adjustment to the twin wellbore trajectory such that the requisite proximity to the existing well could be maintained.

CUSTOMER VALUE

Scientific Drilling’s efficient ranging practices saved the client valuable rig time. Contributing factors are:

1. The Lodestone system acquires data during the time that pumps are brought up to speed prior to transmitting the MWD survey.

2. Continuous BTotal measurement is obtained while drilling and does not require repeat passes.

3. The high detection range of the Lodestone system enabled the operator to select the most convenient surface location for the twin well and avoided the need to sidetrack out of the existing well.

4. BHA design was not significantly impacted by the ranging technologies; Lodestone only requires a short bit sub in the drilling BHA and MagTraC does not require additional equipment above the MWD tool, thus allowing the directional performance of the BHA to be similar to conventional directional BHAs.

YOU MAY ALSO BE INTERESTED IN

Relief Well Intercept with Active and Passive Magnetic Ranging