Navigation

High-Quality PLT and MFT Data from Ultra Hot Gas Well

APPLICATION

/ Production Logging

/ Well Integrity

TECHNOLOGY

/ Cased Hole Services

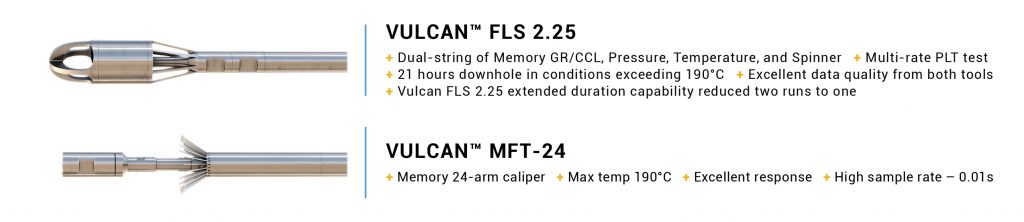

/ Vulcan FLS 2.25

/ Vulcan MFT-24

LOCATION

/ North Sea

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

The operator of an HPHT well in the North Sea required accurate information from their high-production gas well for updated reservoir modeling.

The client required obtaining detailed production logging data from a single run. Therefore, including meeting the objectives of Selective Inflow Performance (which imposes logging at multiple flow rates) and assessing the existence of any crossflow across the two main distances. Another challenge was the well’s downhole temperature of 193°C (379°F). However, the total anticipated run time for the program was up to 23 hours.

In addition to the PLT data, they required a multi-finger caliper to evaluate the condition of the production liner.

SCIENTIFIC SOLUTION

Scientific Drilling International’s (SDI) solution for the PLT was the Vulcan FLS 2.25 system positioned in memory mode. As a result, a tandem tool-string of GR/CCL, Pressure, Temperature & Spinner provided confidence in achieving the data-gathering goal.

SDI’s Vulcan MFT-24 was also integrated into the tool string. To clarify, with a temperature rating of 220°C (428°F). Furthermore, the Vulcan MFT-24 provided ideal results for meeting the production liner evaluation objectives with a fast-sampling rate of 0.01s. Therefore, high-resolution data could be acquired.

CUSTOMER VALUE

The Vulcan FLS 2.25 reduced what would usually entail two runs to meet the production logging goal to one. Thus, providing considerable cost savings to the client while significantly reducing the project’s risk profile.

The Vulcan MFT-24 memory caliper provided detailed insight into the condition of the production liner that revealed the presence of irregularities. As a result, this would require regular monitoring to help maintain the well’s integrity.

YOU MAY ALSO BE INTERESTED IN

Optimizing Lateral Length with Acoustic Sensors in ULT tool