Navigation

MPNN Frac Evaluation

CUSTOMER CHALLENGE

The customer’s gas reservoir required hydraulic fracturing to move production. An inert (high capture cross-section) ceramic frac proppant position to assess the occurring break of the formation. However, the customer sought pulsed neutron technology to detect the inert tracer to transport in memory mode.

SCIENTIFIC SOLUTION

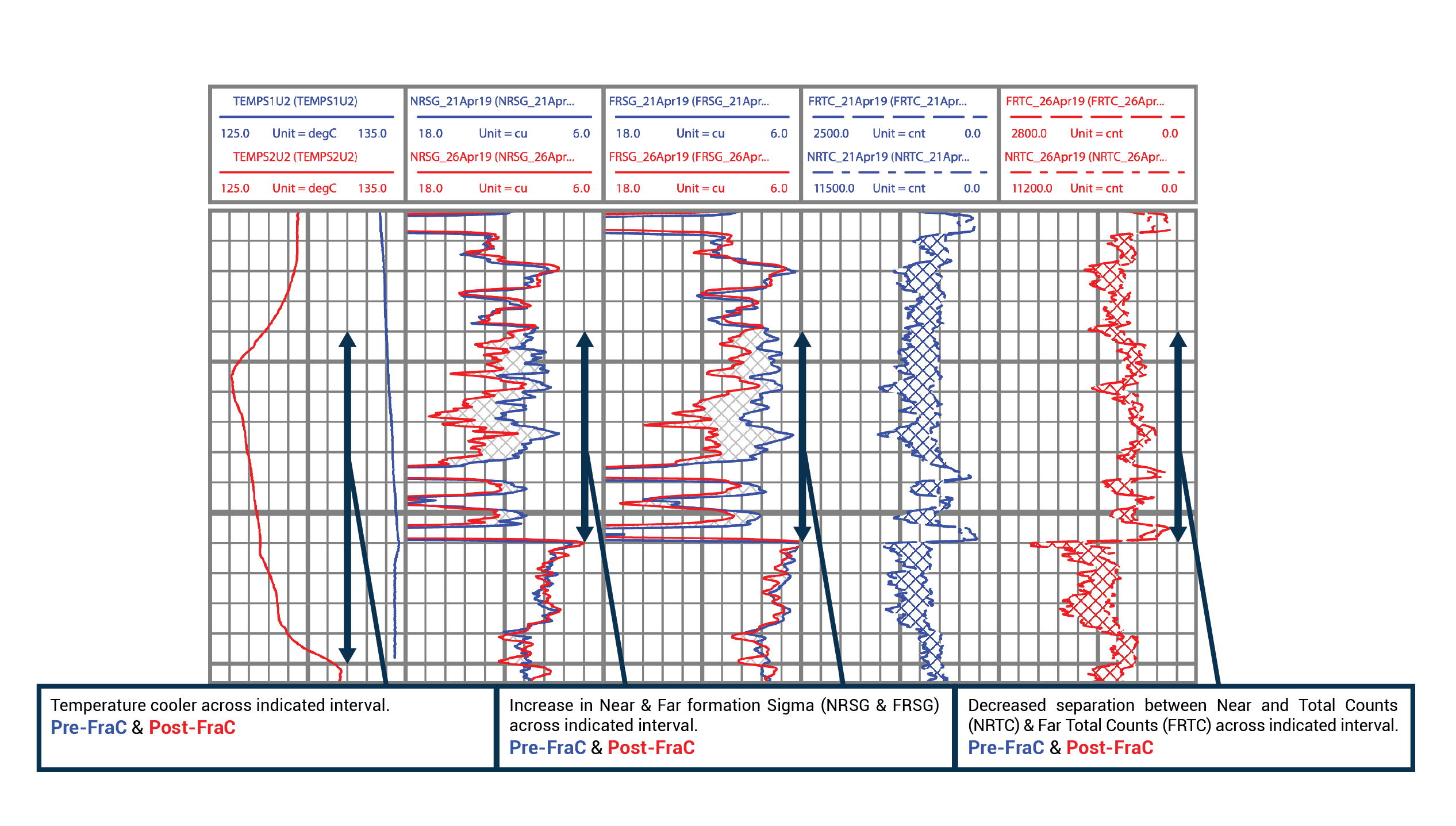

Scientific Drilling’s Memory Pulsed Neutron-Neutron (MPNN) technology was the perfect solution. The MPNN logs before and after the frac operation inside 4-1/2″ tubing with two passes completion on both runs. The output Sigma data and Near/Far Total count separation identified the frac zone to the high capture cross-section of the proppant used.

CUSTOMER VALUE

The MPNN helped avoid the need for hazardous radioactive tracers, vastly improving the HSE factor of the project. The ability to bring the MPNN on a slickline removed any need for an electric line. With an association pressure control burden and the environmental implications of grease injection. The reliability and accuracy of the MPNN provided apparent detection of the frac height. In addition, the efficacy of the frac operation confirms.

Learn more at: Scientificdrilling.com/CHSPDF File