Navigation

Optimizing Lateral Length with Acoustic Sensors in ULT tool

APPLICATION

/ Geosteering

/ Engineered Completions

/ Wellbore Imaging

/ Sourceless Porosity Measurement

TECHNOLOGY

/ Logging While Drilling (LWD)

/ Unconventional Logging Tool (ULT)

/ Wave Propagation Resistivity (WPR)

/ Pressure While Drilling (PWD)

/ Measurement While Drilling (MWD)

/ Falcon Mud Pulse (MP) MWD

LOCATION

Permian Basin, TX

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

A major Permian basin operator sets to drill an appraisal well in a newly acquired oil/gas lease. The completion plan for the horizontal section was to have at least 5000′ lateral wellbore placement in the highest porosity zones of the target formation. The natural gamma radiation from the limestone formation was low. So, dependable LWD resistivity measurements in real-time would require them to stay in their target zone. Log correlation between LWD porosity and LWD resistivity implemented in the lateral length determination.

SCIENTIFIC SOLUTION

For real-time geosteering and wellbore surveying, Scientific Drilling International’s (SDI) Falcon Mud Pulse MWD system deploys for accurate and reliable data transmission. Furthermore, the system provides six-axis survey data. For example, the MWD system equips with Pressure While Drilling for real-time monitoring of ECDs and mud weight optimization.

Geosteering requires both Gamma Rays and Resistivity. Therefore, SDI’s WPR system interconnects with the Falcon MP MWD system for accurate Deep Phase Resistivity curves in 2Mhz and 400kHz frequencies. This dual frequency, spacing, and fully compensated resistivity collar gave the geosteering team the formation measurements reading over 6 feet from the wellbore.

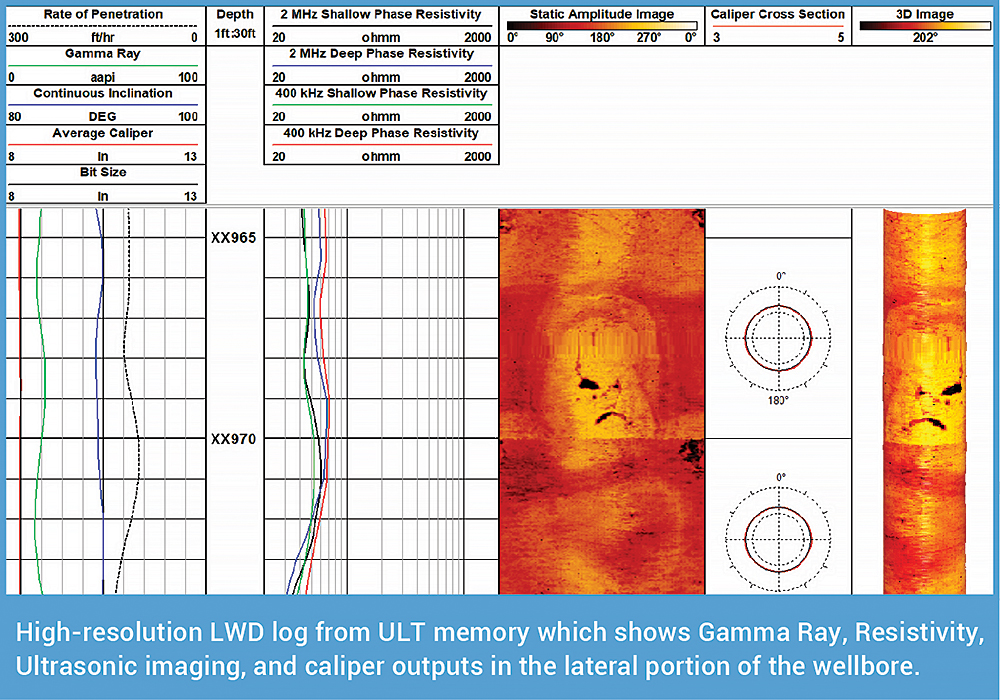

SDI’s Unconventional Logging Tool (ULT) was also included in the BHA between the MWD and Resistivity collars to image the wellbore. For instance, in the oil-based mud system, provide source-less reservoir porosity measurements. This unique LWD tool uses an integrated sensor design for optimal BHA bit-to-sensor distances. Therefore, lowering LWD tool costs. However, with its ability to log ultrasonic images and traditional unipole acoustic waves. This technology reduced the risk of running nuclear sources downhole for porosity measurements and logged high-quality images of the borehole wall for fracture evaluation.

CUSTOMER VALUE

By running LWD technology for gamma ray, resistivity, ultrasonic imaging, and unipole sonic, the operator could steer the well in the high porosity zones. In addition to fulfilling the completion requirement of having 5000ft of the vertical section in the thin target zones. Since the ULT’s unipole sonic could measure the formation’s porosity, the operator did not need to run nuclear sources in the drilling BHA. Therefore, lowering risk and reducing costs.

YOU MAY ALSO BE INTERESTED IN

Chasing Sub-Seismic Sandstone Reservoirs with At-Bit Azimuthal Gamma Ray and Inclination