Navigation

Parted Tubing in SAGD Well Captured in 3D Images

APPLICATION

/ Well Integrity

/ SAGD

TECHNOLOGY

/ Cased Hole Services

/ Vulcan™ MFT-24

LOCATION

/ North America

DOWNLOAD CASE HISTORY

/ PDF File

CLIENT CHALLENGE

An operator had performed milling of the 5-1/2″ liner of its steam-assisted gravity drainage (SAGD) well and had doubts about the status of the wellbore upon completion of the remedial activities. Consequently, the operators sought to ascertain an accurate picture of the condition of the downhole tubular within the zone of the milling and along the wellbore in general.

The horizontal well section in the milling zone necessitated coiled tubing conveyance, and uncertainty over the bottom hole temperature during the well intervention increased risk factors about selecting the most appropriate cased hole evaluation technology for this case.

SCIENTIFIC SOLUTION

Scientific Drilling’s Vulcan™ MFT-24 multi-finger caliper selection provides the answers that the operator needs. The memory caliper is a high-resolution, high-accuracy wellbore inspection technology rated to 220°C (428°F). In combination with gamma-ray, CCL, pressure, and temperature sensors, the tool transports to the bottom of the log interval, and upon the fingers opening, logging conducts to the surface at a speed of 10m/min and a sample rate of 0.02 s. Upon retrieval of the data on the surface, reveal a maximum downhole temperature of 160°C.

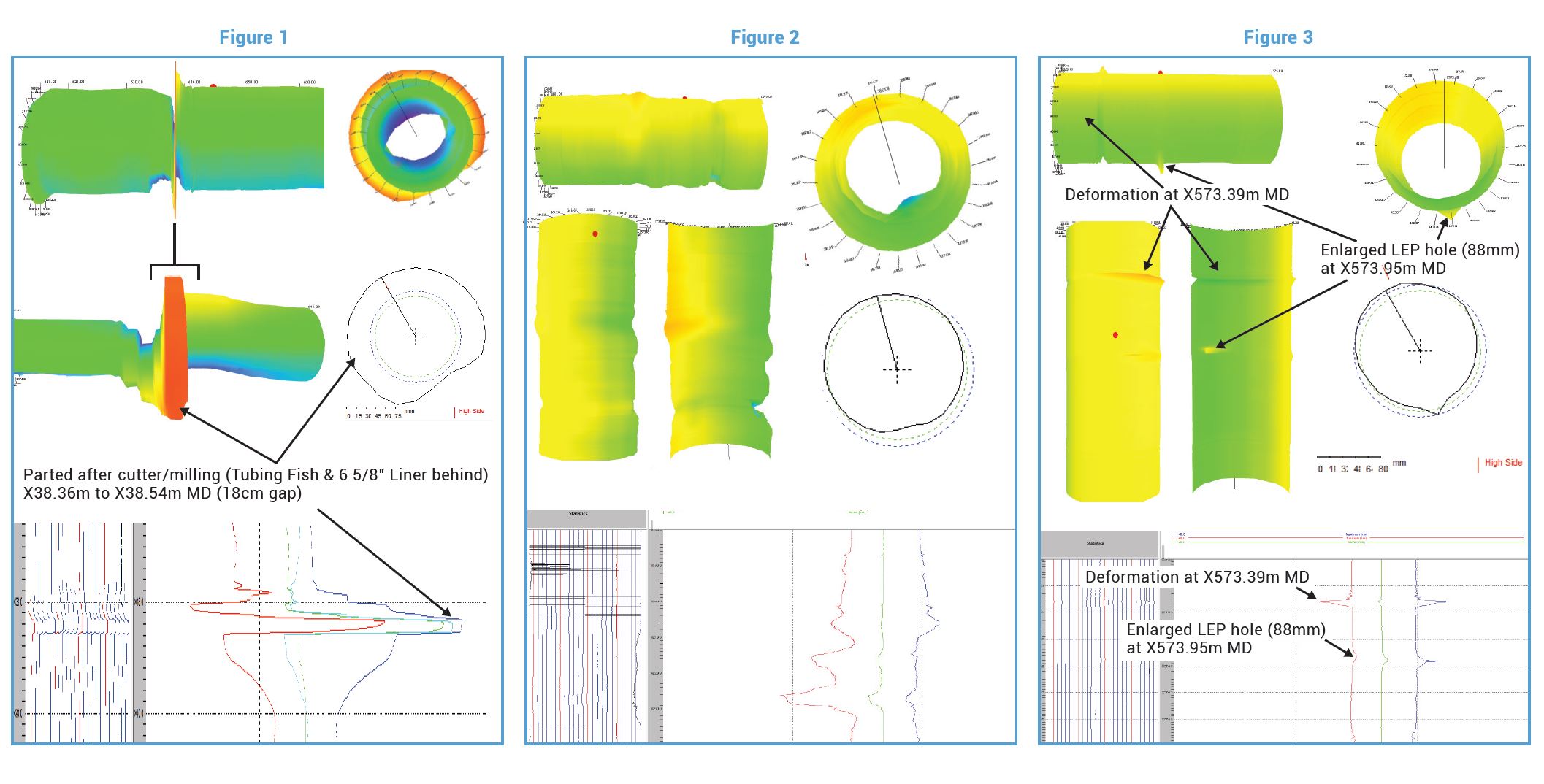

As Figure 1 shows, a parting of the 5-1/2″ tubing identifies with a gap of 40cm between the tubing and tubing fish. Other notable features of interest include low-side deposition (figure 2) and an enlarged limited entry perforation (LEP) (figure 3).

client VALUE

The precise identification of the tubing fish provided the necessary information for the operator to conduct further remedial operations to return the well to its online status. The high-temperature rating of the Vulcan™ MFT-24 multi-finger caliper negated any need for comprehensive wellbore cooling, resulting in cost and time savings for the operator.

YOU MAY ALSO BE INTERESTED IN

Precise Wellbore Placement with New Smart Motor

Precise Wellbore Placement with New Smart Motor