Navigation

Relief Well Intercept with Active and Passive Magnetic Ranging

APPLICATION

/ Relief Well

/ Relief Well Planning

/ Well Control

/ Magnetic Ranging

/ Wellbore Surveying

TECHNOLOGY

/ BlackShark Active Ranging System

/ MagTraC Passive Ranging

/ Falcon MP MWD

/ TiTAN22 Performance Drilling Motor

/ Keeper gyroMWD

LOCATION

West Texas, Permian Basin

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

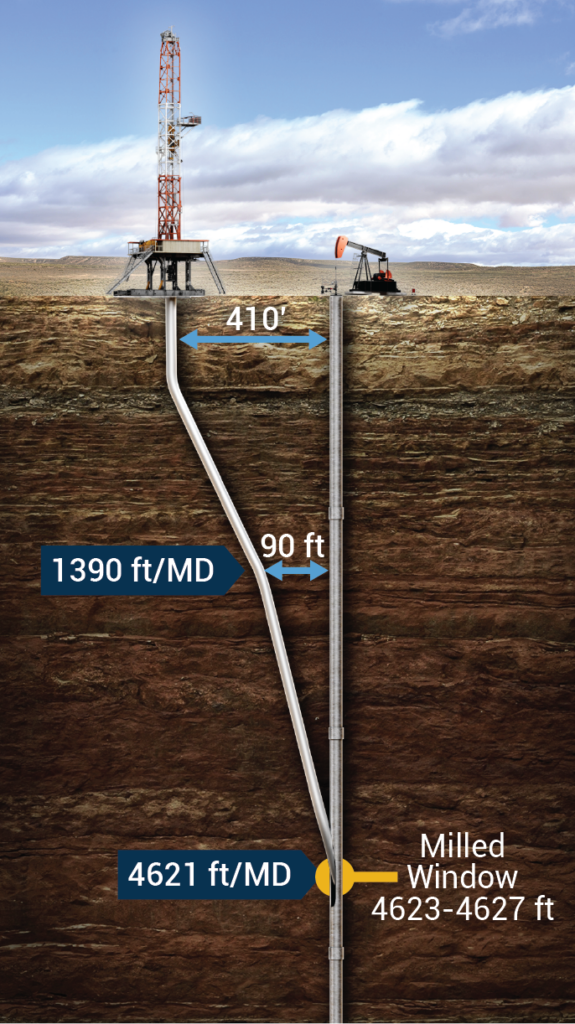

The client had a CO2 storage well blowout during workover operations. Following the installation of a new wellhead and excavation of the area surrounding the well being, the well was still producing water, CO2, and H2S gas at surface. The target well needed to be intercepted and killed to stop the flow of water and gas at surface.

A number of challenges would be present in the drilling of the relief well: the 5.5″ casing needed to be intercepted in a formation with CO2 and H2S present, poor magnetic signal was possible due to degraded casing from the CO2 and H2S, and possible high-pressure from target well at intercept depth needed to be considered.

Regarding the drilling of the relief well, the target well had inclination-only surveys; as such, the azimuthal path of the target well was unknown. This would require the relief well to drilled in a “locate and follow” manner. Ranging could only be done after 1380 ft MD due to needing to case off the “red beds” problem zone, compounding the difficulty of finding the target well.

SCIENTIFIC SOLUTION

The relief well was drilled using a complete package of SDI technology and services: Active and Passive Ranging, Directional Drilling, MWD, and Wireline Services. The target well was successfully intercepted, milled into, and killed at a depth of 4621 ft MD.

Active Magnetic Ranging Technology: Scientific Drilling’s BlackShark Active Magnetic Ranging System was used for the intercept. A current was injected into the formation, and a magnetic field was emitted from the target well casing. BlackShark detected this magnetic field and used it to pinpoint the well position.

Passive Magnetic Ranging Technology: Scientific Drilling’s MagTraC Continuous B-Total was used to monitor the target well while drilling, determining if the relief well was converging or diverging from the target well. Upon closer distance to the target well, Continuous BTotal was used to identify casing collars in the target well.

Advanced Wellbore Surveying Technology: Scientific Drilling’s Keeper GyroMWD was used to steer the well on approach to the target well, mitigating magnetic interference challenges and ensuring accuracy in the intercept.

CUSTOMER VALUE

Following the kill of the target well, surface fluid communication became static and drained into the target well. The client was able to successfully pump cement from the relief well into and ultimately plug the target well.

Accuracy and Precision of Magnetic Ranging: The BlackShark Active Magnetic Ranging System provided high-accuracy measurement of the target well azimuth, enabling a precision intercept without the need for wellbore sidetracks. Continuous BTotal provided real-time monitoring of the target well, reducing the total required ranging runs.

Efficient Operations: The intercept occurred 29 days from the spud date. The shorter drilling duration compared to typical relief wells demonstrated the efficiency of the solutions deployed. The target well was also intercepted 200ft earlier than planned due to SDI’s competency in ranging, planning, and directional drilling.

Successful Intercept: The well was intercepted on the first attempt, showcasing the efficacy of the chosen SDI technologies and techniques.

Best Practices: This project demonstrated that planning and drilling an intercept relief well in a short amount of time is possible. Proper planning, accurate Magnetic Ranging technology, good communication with all parties, and adherence to safety procedures contributed to the project’s success.

YOU MAY ALSO BE INTERESTED IN

Vulcan™ MFT-40 Discovers Inadvertent Sidetrack