Navigation

Precise Wellbore Placement with New Smart Motor

APPLICATION

/ Wellbore Placement

/ Geosteering

TECHNOLOGY

/ Directional Drilling Services

/ Smart Motor- TiTAN22 Performance Drilling Motor with at-bit electronics integrated into the motor mandrel

/ Logging While Drilling (LWD)

/ BitSub Azimuthal Gamma Ray/Inclination sensor

/ Measurement While Drilling (MWD)

LOCATION

/ Gulf Coast, Southeast Texas

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

Re-development of mature oilfields requires new ideas and supporting technology to untap trapped reserves. An operator interested in a field initially developed 70-years ago found a thin layer of oil trapped at the top of their reservoir.

Instead of performing an economically prohibitive Enhanced-Oil-Recovery (EOR) operation, they elected to drill a horizontal well to produce from the trapped “attic-oil” located within the top 5 feet of the main sandstone reservoir.

Precise wellbore placement was needed to maximize oil production while staying above the oil/water contact.

SCIENTIFIC SOLUTION

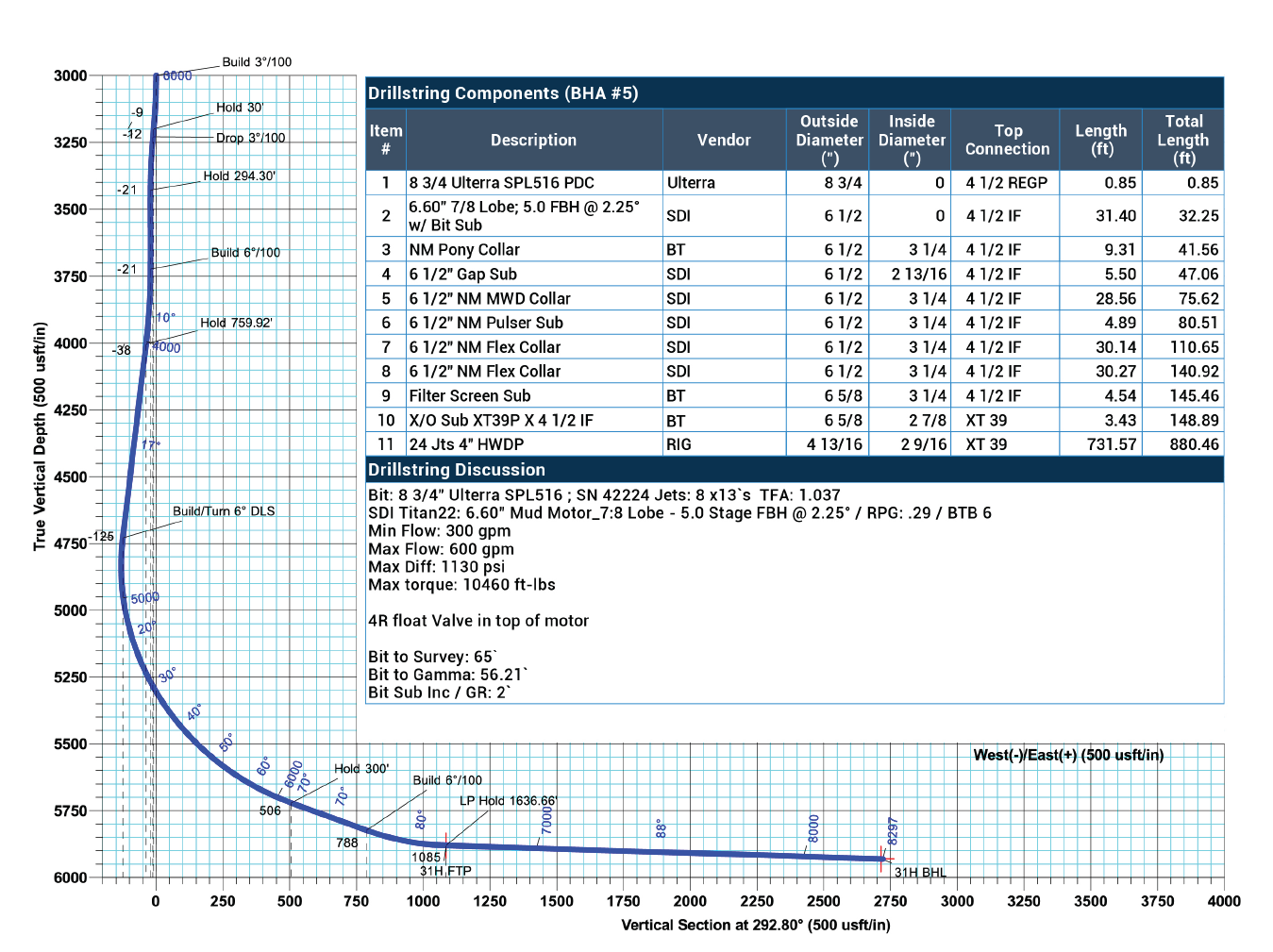

Scientific Drilling’s BitSub LWD sensor provides at-bit gamma ray and inclination, allowing critical geosteering decisions about target changes to be made proactively. The planned well design called for the curve section to be landed in a shale cap 2’ TVD above their target zone. An intermediate casing string was to be run and cemented to ensure the lateral would be well-positioned to stay in the oil zone.

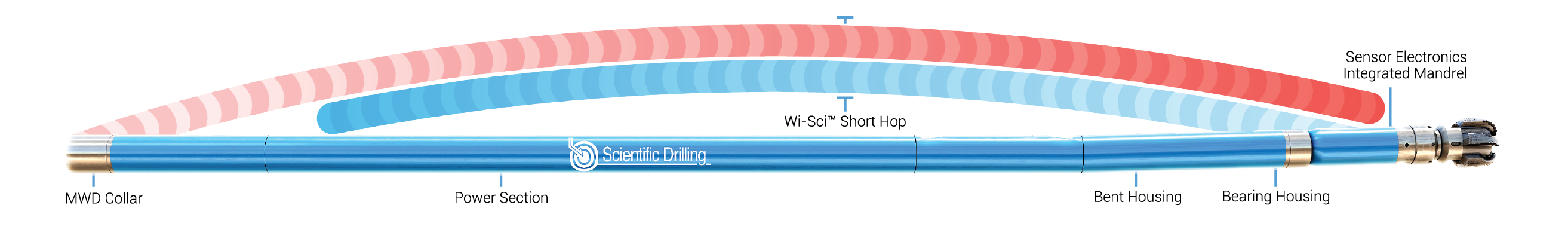

Multiple soft sandstone formations above the target presented challenges for build rates through the curve. To ensure precise well placement, the BitSub electronics were run in the integrated TiTAN22 motor mandrel.

This instrumented Smart Motor utilized a fixed-bend housing set at a 2.25° bend for optimal motor yields.

CUSTOMER VALUE

By utilizing the instrumented Smart Motor to drill the intermediate & curve section, the operator was able to reduce their operating costs by eliminating the utilization of a rotary steerable system (RSS) in this hole section.

The at-bit gamma ray measurement allowed the geosteering team to effectively land on target, improving the oil production potential at the beginning of the lateral.

The at-bit inclination facilitated real-time motor yield monitoring to decrease Invisible Lost Time (ILT) associated with build rate variations while drilling the curve.

YOU MAY ALSO BE INTERESTED IN

Complex Plug and Abandonment in Los Angeles Metropolitan Area