Navigation

Pulsed Neutron-Neutron and Spectral Noise Gas and Flow Detection

CUSTOMER CHALLENGE

As part of preparations for plug and abandonment activities, an operator of an offshore gas field was required to obtain data on the status of shallow gas pockets and gas flow in the annulus.

A dual data acquisition approach was demanded, deploying pulsed neutron technology to identify the presence of formation or near wellbore gas and noise tool to detect flow in the annulus. For simplified well intervention, slickline was the preferred method of tool conveyance, thereby necessitating memory technologies.

SCIENTIFIC SOLUTION

Scientific Drilling’s memory pulsed neutron-neutron (MPNN) tool is a highly dependable pulsed neutron technology that excels in gas environments compared with gamma-ray detecting alternatives. The chosen noise tool was a broad-spectrum memory leak and flow detector.

The MPNN was deployed first, followed by the noise tool.

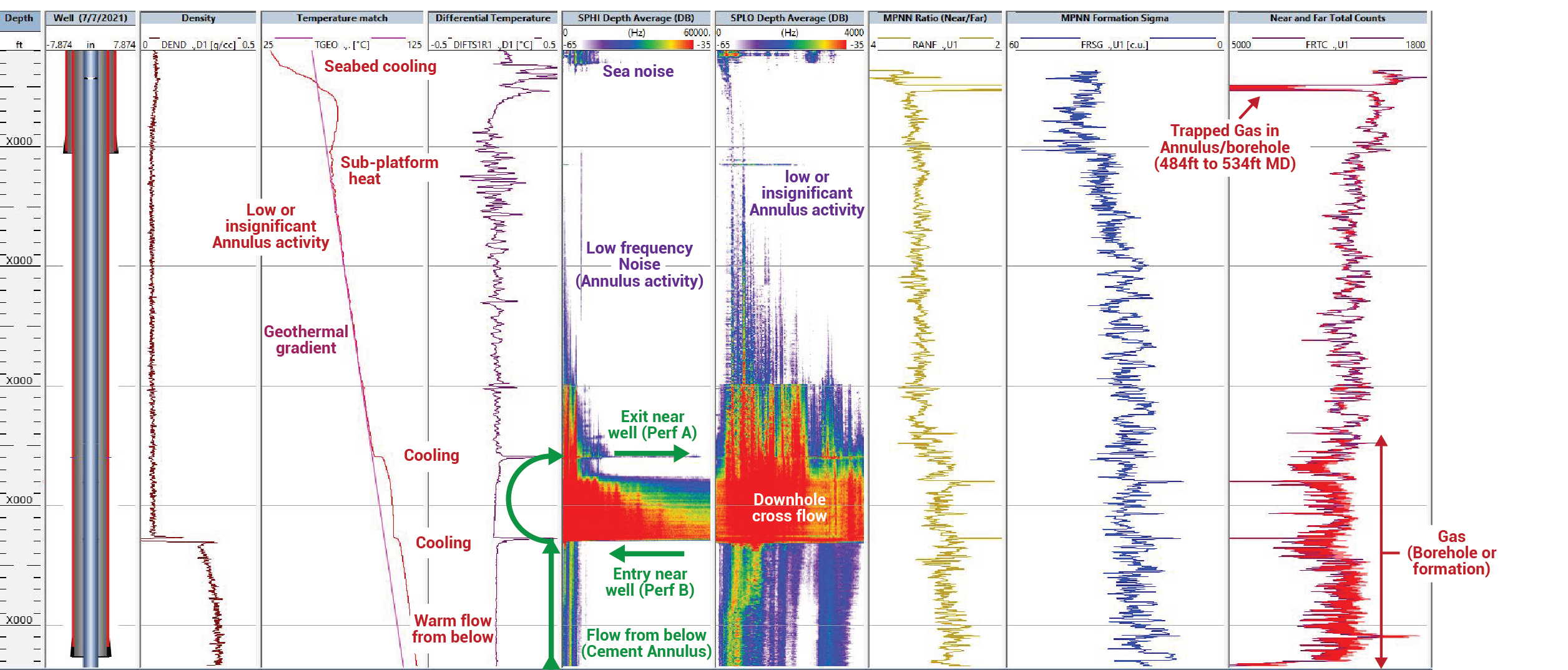

As figure 1 shows, across the bottom section of the log (top perforation ‘A’ to below the logged interval at X340Ft MD), the MPNN Near/Far Total counts detected gas (red shading) within the near wellbore/formation which was consistent with Noise log activity measuring flow from below and possible cross-flow between zones (B and A). The MPNN Near/Far Total counts (red shading) also revealed trapped gas near the top of the logging interval (X84Ft to X34Ft MD). An increase in Near/far total counts was observed, but it only affected the borehole and not the formation, signifying near wellbore gas.

CUSTOMER VALUE

Scientific Drilling’s memory data acquisition solution provided cost savings, operational efficiencies and lowered HSE risks through the avoidance of electric-line and associated pressure control equipment. The combination of the MPNN and noise tool provided confirmation of the location of the gas zone and its dynamic behaviour. With this information, the operator was able to plan P&A activities with confidence.

YOU MAY ALSO BE INTERESTED IN

Complex Plug and Abandonment in Los Angeles Metropolitan Area