Navigation

SDI’S GYRO BATCH SURVEYS OFFER SIGNIFICANT TIME AND COST SAVINGS

APPLICATION

/ Pad Drilling (Multi-Well)

TECHNOLOGY

LOCATION

Pennsylvania, US

DOWNLOAD CASE HISTORY

/ PDF File

CLIENT CHALLENGE

The operator was rotary drilling the top hole to 1,000 ft without surveys before setting the surface casing. The drilling was completed in a batch

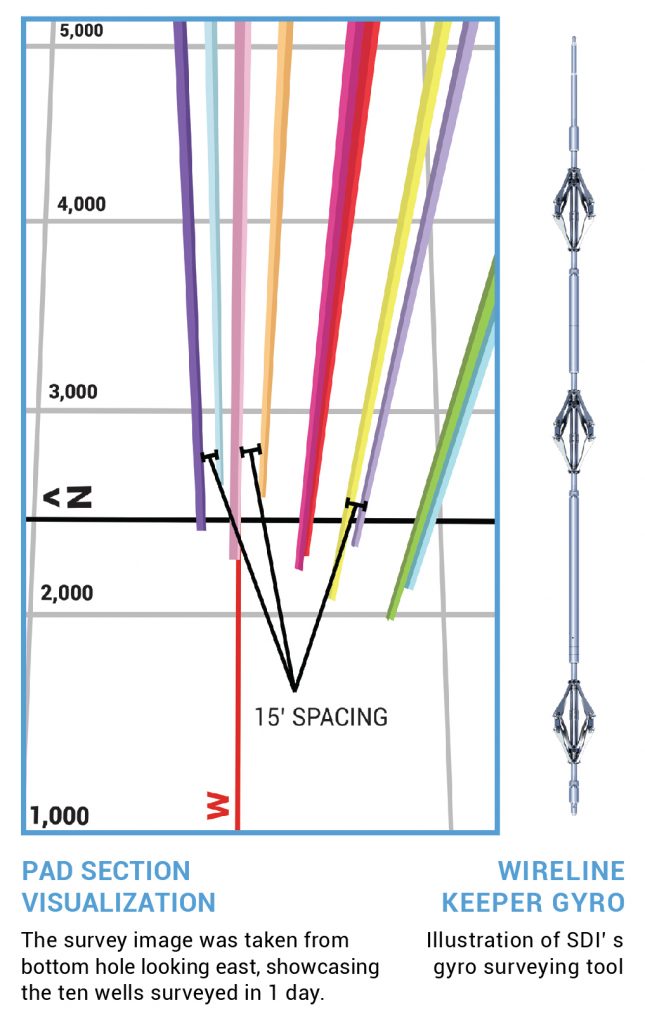

drilling operation using a top-hole rig. Anticollision was a significant concern in the intermediate hole section due to well spacing as close as 15 ft. Due to the tight spacing requirement of the gyro survey before drilling ahead after the curve, the lateral rig moved in. An additional two hours of rig time for each well surveyed.

SCIENTIFIC SOLUTION

Scientific Drilling deployed the Wireline Keeper Gyro, utilizing the Casing Centroller System. This service was conducted with an SDI wireline unit, eliminating the need for a drilling rig. SDI’s centroller running gear provided precision alignment with the wellbore and ensured smooth operations while running at high speeds.

The Keeper’s proprietary low-angle high-speed mode enabled wireline running speeds up to 300 (ft/min) in a continuous survey mode. The tool reduced the survey time for each well to less than 45 minutes (a 63% reduction). SDI’s proprietary software provided constant feedback on tool performance, ensuring the survey met the anticollision needs of the client and conformed to our ISCWSA-compliant instrument performance model.

According to the pre-job planning requirements, SDI mobilized two survey teams and additional equipment. The conditions allow one group to ensure all tools are set up and calibrated for the next well while the current well is surveyed, saving extra time.

CLIENT VALUE

Batch surveying all ten wells in less than 12 hours saved the customer 20 hours of rig time and significantly reduced the cost per survey. The operator stated that the SDI solution resulted in an estimated $55,000 reduction in operating costs, equating to more than 50% in total savings. Due to this overall success, they intend to utilize SDI’s surveying solution on future pad drilling projects.

YOU MAY ALSO BE INTERESTED IN

MagTraC MWD Ranging™ & gyroMWD Bypass Fish and Re-enter Open Hole