Navigation

Staying “in-zone” with at-bit gamma ray imaging from BitSub

APPLICATION

Geosteering

TECHNOLOGY

BitSub at-bit azimuthal gamma ray/inclination sensor

TiTAN22 performance drilling motor

LOCATION

South Texas

CUSTOMER CHALLENGE

As operators increasingly realize the benefits of drilling horizontal wells to untap oil reserves, new LWD technology is helping them maximize their return on investment (ROI) by drilling wells in their designated target zones for optimal production strategies. A South Texas operator drilling a mature oil field composed of sandstone reservoirs needed to ensure they kept drilling costs low without sacrificing production.

Previous wells involving multiple sidetrack operations due to drilling out of target zone led the operator to look for a solution to their geosteering challenges.

SCIENTIFIC SOLUTION

Scientific Drilling’sBitSub LWD tool provided the operator with high-resolution Gamma Ray imaging less than 2 feet from the drill bit.

These real-time measurements allowed the geosteering team to make critical decisions about target changes before the wellbore exited the pay-zone. This proactive approach to well placement with at-bit LWD measurements was used in conjunction with the high-performance TiTAN 22 drilling motor to maintain high rates of penetration (ROP) and reduce days per well. Directional drilling specialists were able to use the at-bit inclination from the BitSub LWD tool to recognize BHA directional tendencies, as well as motor dogleg output to “paint the line” of the well plan’s target inclination.

CUSTOMER VALUE

By utilizing the BitSub LWD tool to geosteer the well “in-zone”, the operator was able to maximize their oil production by increasing wellbore exposure to the hydrocarbon-rich sandstone reservoir target. The at-bit measurements enabled the well to be drilled as close to the target line as a rotary steerable system (RSS), but without the additional costs. No downhole failures resulted in zero NPT and reduced overall well costs.

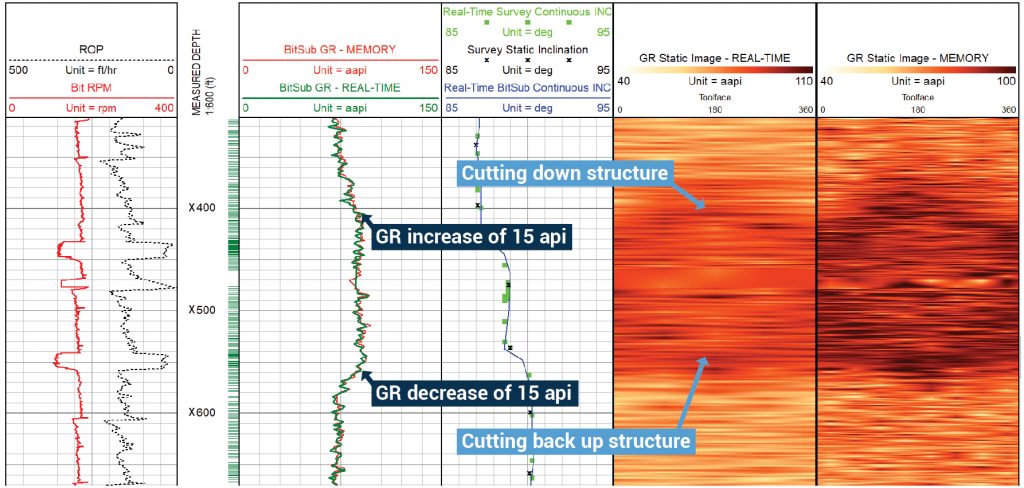

Below: BitSub gamma ray image log with real-time and memory data.

Images showing stratigraphic marker within the target window.