Navigation

Thermal Enhanced Oil Recovery (EOR) well integrity evaluation

APPLICATION

/ Wellbore Integrity

TECHNOLOGY

LOCATION

/ Oil Sands, Canada

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

The operator of a steam-assisted gravity drainage field sought to obtain comprehensive information on the condition of its wellbore tubulars (6-5⁄8″ liner). This included the determination of metal loss and deposition across blank liner joints and flow control devices (FCD), as well as identifying any tubing/liner anomalies such as buckling.

Because of the high deviation, the mode of deployment would be coiled tubing. Another major challenge was an anticipated downhole temperature in the region of 200°C. In addition, each FCD Joint had 4 perforated holes 90° apart, and the operator wanted to verify corrosion over each joint with a high-resolution Caliper.

SCIENTIFIC SOLUTION

The option available to the client was Scientific Drilling’s Vulcan MFT-24, a memory multi-finger caliper with a temperature rating of 220°C.

The log was performed at a speed of 10m/min and sample rate of 0.02 seconds, giving a vertical resolution of 0.12″.

Upon retrieval of the tool at surface, complete data was downloaded and subsequently processed by Scientific Drilling’s on standby log analyst.

CUSTOMER VALUE

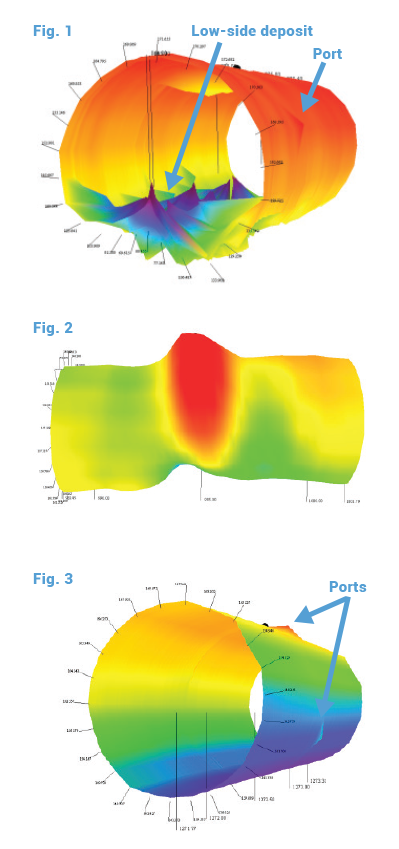

The processed data revealed several anomalies including deposition (figure 1), buckling (figure 2), and flow control ports were also successfully identified (figure 3).

The data and images provided the operator with an understanding of the condition of the wellbore that enabled subsequent remedial well interventions to be planned with accuracy, reducing risk whilst saving time and money.

For more information on the leading caliper technology for high-temperature wellbore inspection requirements, contact your Scientific Drilling sales representative: https://scientificdrilling.com/contact/

YOU MAY ALSO BE INTERESTED IN

Scientific Drilling’s DuraSet service helps client get maximum value by generating accurate data, localizing micro dogleg severity and wellbore tortuosity to improve Electrical Submersible Pump (ESP) placement.