Navigation

ULT DETERMINES FRACTURE COMMUNICATION BETWEEN WELLS

APPLICATION

/ Completion Optimization

/ Collision Avoidance

/ Pad Drilling

/ Geosteering

TECHNOLOGY

/ Unconventional Logging Tool (ULT)

/ Continuous Btotal™

LOCATION

Eagle Ford Shale, South Texas, US

DOWNLOAD CASE HISTORY

/ PDF File

CLIENT CHALLENGE

An operator in South Texas was planning to drill a horizontal well with several close approaches to existing producing horizontal wells. They aimed to cross directly over these offset laterals with the monitoring well and image the wellbore to determine the extent of hydraulic fracturing in different stratigraphic intervals.

The client’s well would drill with an oil-based mud system, preventing traditional LWD micro-imaging technology from being utilized— critical information regarding the stress anisotropy changes near these close approaches. Therefore, the accuracy of the drainage models for the area is required. Furthermore, to gain a time-lapse view of the wellbore’s induced fracture features, the LWD imaging tool ran in the drilling BHA. Subsequent operations of back-reaming out of the hole after reaching total depth perform.

SCIENTIFIC SOLUTION

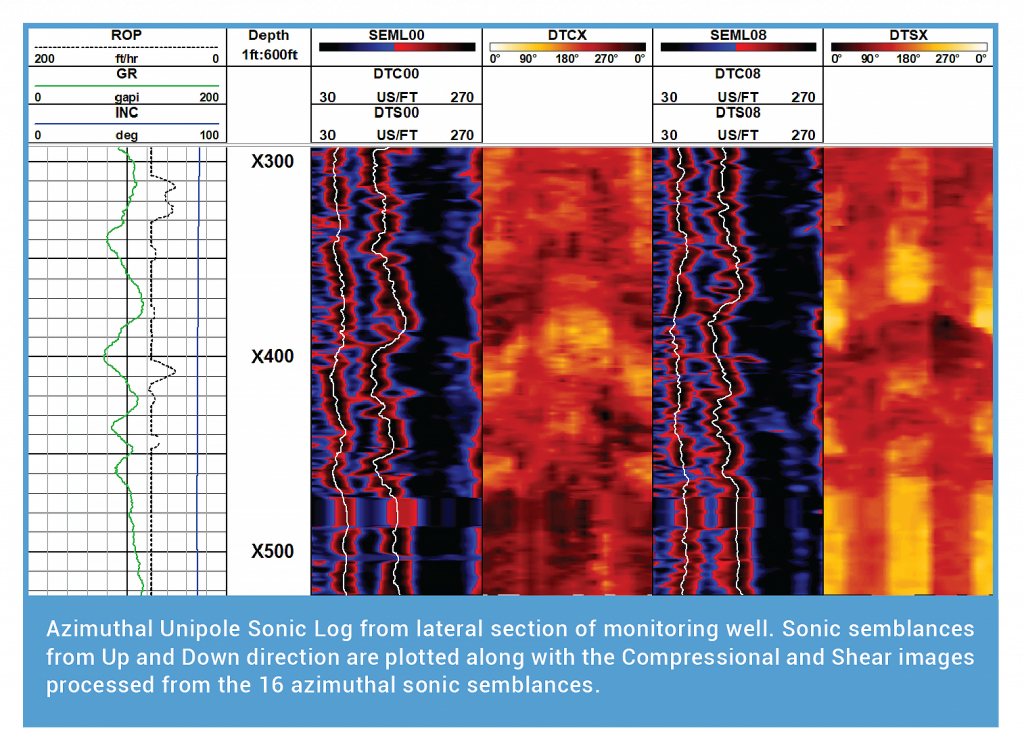

Scientific Drilling International (SDI) utilized Continuous Btotal™ from the MWD survey sensor to ensure collision avoidance. SDI’s new Unconventional Logging Tool (ULT proposed to the operator for identifying fractures in oil-based mud systems. The ULT special LWD tool measures spectral gamma rays, 128-sector ultrasonic images, borehole caliper, and azimuthal sonic in an integrated collar design that is only 15ft long. The ULT would be run above the MWD tool so that the bit-to-sensor for the MWD surveys and continuous B-total for ranging was not affected.

The proximity to the offset wells proactively monitors in real-time as the monitoring passes within 30ft center-to-center of an existing producer well. Expedited turnaround time of the ULT data processing & interpretation performed to adjust the depth ranges of repeat passes of the drill-pipe transport wireline logs before starting production casing operations.

CLIENT VALUE

The operator avoided collision with the offset wells using Scientific Drilling’s LWD and Magnetic Ranging services. For instance, the operator obtains high-quality logging measurements for fracture identification and stress orientation.

With the high-resolution data acquired by the ULT, the operator improved the accuracy of the geomechanical models for predicting production. Therefore, mapping hydraulic fractures across multiple wells for optimal well spacing and completion techniques.

YOU MAY ALSO BE INTERESTED IN

ULT Logs Wellbore Stresses in Close Proximity to Saltwater Disposal Well