Navigation

Wireless HDD River Crossing

APPLICATION

Trenchless Horizontal

Directional Drilling

TECHNOLOGY

Wireless HDD Positioning & Steering

Systems, Pressure While Drilling (PWD)

LOCATION

Hinton, Alberta, Canada

CUSTOMER CHALLENGE

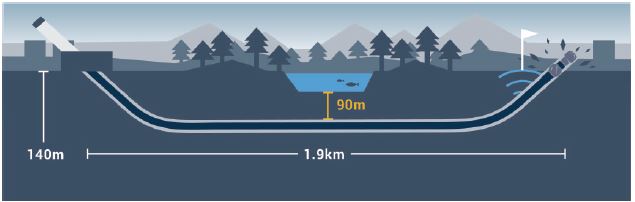

The customer required a 1.9km pipeline to connect two oil and gas processing plants. Still, a local park river in the pipeline trajectory presented strict regulations concerning ground disturbance and water contamination.

To install the pipeline with minimal environmental disturbance, the approach chosen was trenchless horizontal directional drilling (HDD). However, the river crossing posed challenges to conventional wellbore location services. For example, entry and exit points are at least 1 kilometer apart, a resulting trajectory of over 1.8 km in length, and 150m of True Vertical Depth, to name a few. In addition, the project’s economics demanded the most expedient drilling and casing processes possible, with minimal heavy equipment footprint on location.

SCIENTIFIC SOLUTION

Scientific Drilling developed its PunchOut Wireless HDD Navigation system as a completely wireless directional drilling assembly that allows for precise subsurface location and steering of the group at depths of up to 150 meters—an industry first. PunchOut also eliminates the prolonged connection times of traditional HDD steering and location systems.

Scientific Drilling’s Pressure While Drilling tool was used in conjunction with the PunchOut steering system to ensure the wellbore’s annular pressure was below the local geology’s fracture gradient. The tool allowed the project to adhere to regulations by significantly reducing the risk of injecting drilling fluid into the formation and, subsequently, the river.

In addition, by drilling a larger-than-normal borehole, our solution could accommodate the pipe pass-through without following the pilot hole with additional reamer runs. In conclusion, the solution saved an immense amount of time.

CUSTOMER VALUE

The customer would have had to rely on a traditional HDD steering and location system if they did not have the PunchOut System from Scientific Drilling. Therefore, it would have risked project overages due to extended rig time and possible penalties and fines for local park disturbances.

Using the PunchOut system, the customer could drill an accurate wellbore with a minimal surface footprint, significantly reduced survey times, and no need for multiple runs to increase hole size.

The project completion of 325% ahead of schedule—using only 1/3 of the proposed rig time—a savings of approximately $1.5MM.