Navigation

Electrical Submersible Pump (ESP) optimal depth setting determination

APPLICATION

/ Cased Hole Services

/ Wellbore Positioning

/ Production Optimization

TECHNOLOGY

/ DuraSet

LOCATION

/ Middle East

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

The customer’s well had a history of premature electrical submersible pump (ESP) failures. Most recently, an ESP that was installed in April 2020 failed one month later.

To diagnose the cause of failure, the customer decided to obtain insight into areas of mini-dog legs/tortuosity within the 7” Casing (Surface to X082 ft MD), and 5” liner (X854 ft MD to X0041 ft MD) prior to deployment of another ESP of 130.7 ft length and 4.56” OD.

SCIENTIFIC SOLUTION

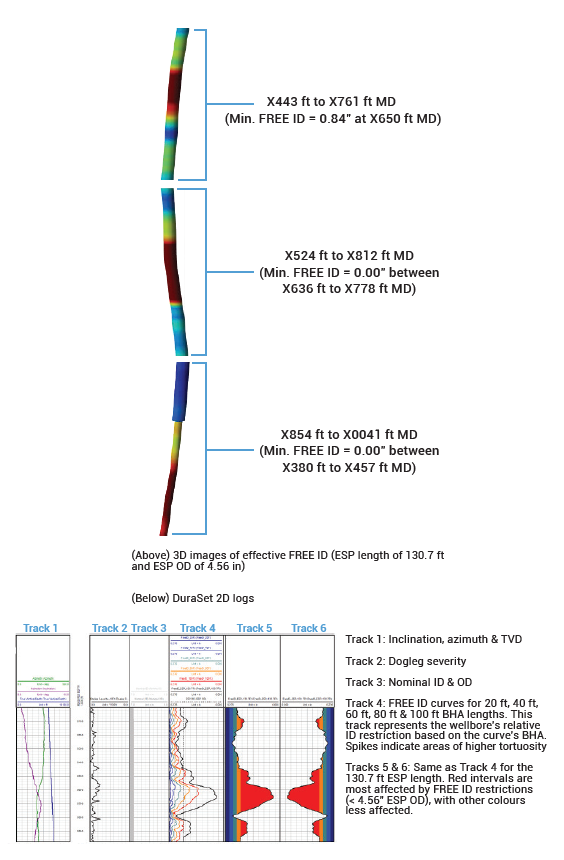

The customer used Scientific Drilling’s DuraSet service, which utilizes a close interval, directional survey to model the wellpath at high depth resolution increments (e.g. 1 ft). This allows identification of mini dog-leg severity/tortuosity and FREE ID calculations for various BHA lengths to determine whether a force/bending moment would be required to get downhole and whether an ESP set across an interval be subject to bending forces.

Using proprietary 3D software modeling, these short-interval measurements provide FREE ID logs for the given ESP dimensions.

Scientific Drilling conducted a wireline tortuosity survey (in-run and out-run) at a speed of 80 ft/min to acquire survey stations approximately every 1 ft.

CUSTOMER VALUE

Prior to receiving the DuraSet data, the customer had decided to set the ESP at X900 ft. However, the DuraSet data revealed that the FREE ID at that depth would apply bending forces to the ESP components and that a better option would be to set the ESP at X300 ft.

The ESP was subsequently set at the newly recommended depth and has been functioning effectively ever since.

The resultant extension of the operating window of the ESP equates to cost savings of approximately $250K.

YOU MAY ALSO BE INTERESTED IN

The MPNN tool is a cost effective way to run pulsed neutron logs on slickline or coiled tubing.