Navigation

Linking Laterals Together with HALO RSS

APPLICATION

/ Multi-well pad optimization

/ Large step-out with 50° inclination

/ Complex 3D curve

/ One-run curve/lateral

TECHNOLOGY

/ HALO Rotary Steerable System

/ Falcon MWD

LOCATION

Northeast US

DOWNLOAD CASE HISTORY

/ PDF File

CLIENT CHALLENGE

An operator in the Northeastern United States intended to optimize lateral well paths while utilizing an existing surface location on an adjacent lease. Therefore, their development strategy hinged on the ability to drill their intermediate section with a large step-out, a complex 3-D curve, and to stay 100% in-zone for their lateral area. This intricate, well design sought to be unachievable with conventional mud motor BHAs due to the excessive directional control requirement.

SCIENTIFIC SOLUTION

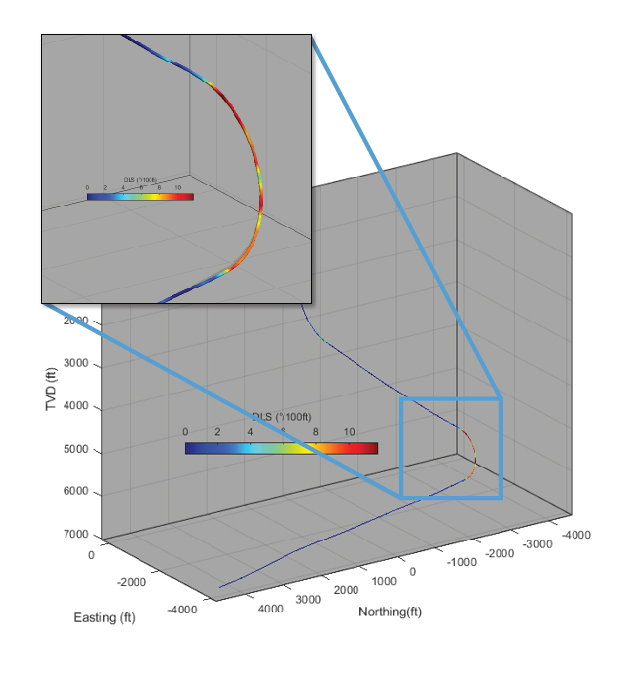

Scientific Drilling proposed utilizing its HALO High-Performance Rotary Steerable System to drill the intermediate section’s step-out to 50° inclination, then holding this tangent for approximately 4000’ until KOP. After all, reaching KOP, a new HALO, BHA, was to be configured in the “flex” configuration to drill the curve and lateral section.

With the HALO system’s ability to build up to 15°/100, the drill can curve and lateral during a single run. Meanwhile drilling the horizontal section, the HALO’s autopilot feature minimizes unexpected dogleg severity by using inclination-hold and azimuth-hold for a smooth wellbore and normal tripping operations after reaching TD.

CLIENT VALUE

By utilizing the existing multi-well pad location, the operator could reduce their surface footprint and optimize the production equipment utilization already on the pad. Therefore, this unique, well design, they combined two short laterals into one longer lateral.

The HALO system used in the intermediate section performed a flawless execution of the planned 4°/100 build in the step-out and held the tangent with minimal dogleg severity until KOP. After all, picking up the HALO “flex,” BHA at KOP, drill the curve and lateral in a single run. This BHA consistently outputs doglegs 10-11°/100 through the 3-D curve to ensure the well lands on target. In total, 10,589’ of production section drills with only 88.93 circulating hours for the run. Average lateral doglegs were 0.89°/100, which allowed for most tripping operations to be done simply on elevators after reaching TD.

YOU MAY ALSO BE INTERESTED IN

Excellent PLT Data in Tight Restriction Well