Navigation

Excellent PLT Data in Tight Restriction Well

APPLICATION

/ Production Optimization

/ Cased Hole Services

TECHNOLOGY

LOCATION

North Sea

DOWNLOAD CASE HISTORY

/ PDF File

CLIENT CHALLENGE

The operator intended to access new reserves in a developed oil field. The reserves required a strategic plan of re-entering older producing velocity string installed in a gas producer to help enhance performance hindered by water production. The operator wanted to evaluate the downhole flow profile and identify gas and water entries across the perforated 5″ liner, choosing to deploy a memory production logging tool (MPLT). Therefore, the presence of a 1.688″ restriction limited the options for the deployment of PLT technology that could be relied upon to acquire high-quality measurements in the 5″ liner.

SCIENTIFIC SOLUTION

SlimFlow is Scientific Drilling’s slimline MPLT system. It was ideal for the well parameters with a maximum outside diameter of 1.5″. The tool comprises the standard sensors found in a PLT string, including Tuning Fork Density, Capacitance, In-line spinner, and Fullbore spinner.

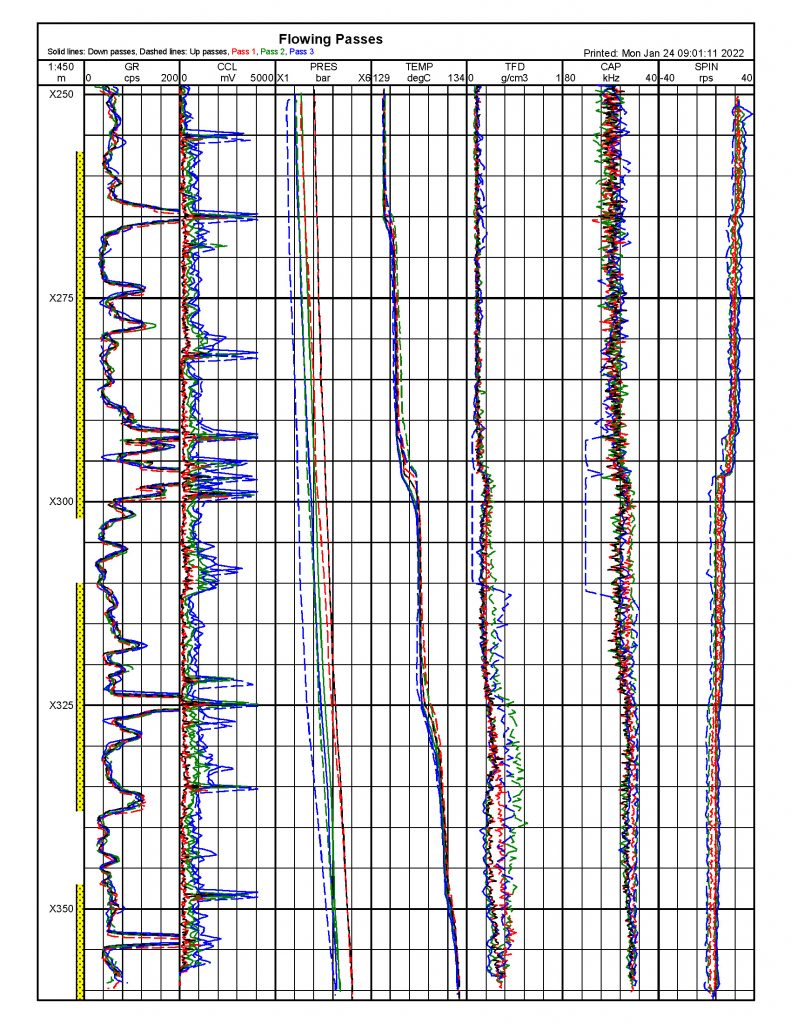

A comprehensive logging program was followed, with passes performed in shut-in and two flow rates. Retrieve complete data from the tool, and the response from all of its sensors was of high quality, as observed in the log plot data.

CLIENT VALUE

By utilizing the SlimFlow MPLT system, the client benefited from a slim MPLT technology solution without compromising data quality. The narrow tool-string configuration provided the added benefit of reducing the disturbance of the flow regime in comparison with a conventional PLT.

YOU MAY ALSO BE INTERESTED IN

One Attempt Well Intersect with Lodestone