Navigation

REAL-TIME PORE PRESSURE PREDICTION USING ULT'S SONIC MEASUREMENT

APPLICATION

/ Pore Pressure Prediction

/ Offshore Drilling

/ Exploration Well

TECHNOLOGY

/ Logging While Drilling (LWD)

/ Unconventional Logging Tool (ULT)

/ Wave Propagation Resistivity (WPR)

/ Pressure While Drilling (PWD)

/ Measurement While Drilling (MWD)

/ Falcon MP MWD

LOCATION

Offshore, Gulf of Mexico

DOWNLOAD CASE HISTORY

/ PDF File

CLIENT CHALLENGE

An operator drilling a well on the shelf in the Gulf of Mexico needed accurate real-time resistivity and sonic data for pore pressure prediction.

The well was an exploration well in an area with a known overpressured gradient. The real-time data needed to be accurate and in high data density so that calculations and trend lines could establish. Furthermore, the data prevents drilling with inadequate mud weights.

SCIENTIFIC SOLUTION

Scientific Drilling’s Unconventional Logging Tool (ULT) tool provided real-time sonic data and resistivity from the Wave Propagation Resistivity (WPR) tool. These two tools, in conjunction, could transmit data to the surface via the Falcon MWD Mud-Pulse System. Having achieved highly reliable and fast data transmission with Scientific Drilling’s solution, the operator gained the confidence to continue drilling to their planned TD. Meanwhile, just above the start of the overpressured zone. Also included in the MWD tool was a Pressure While Drilling (PWD) sensor, which was actively monitoring downhole Equivalent Circulating Densities (ECD).

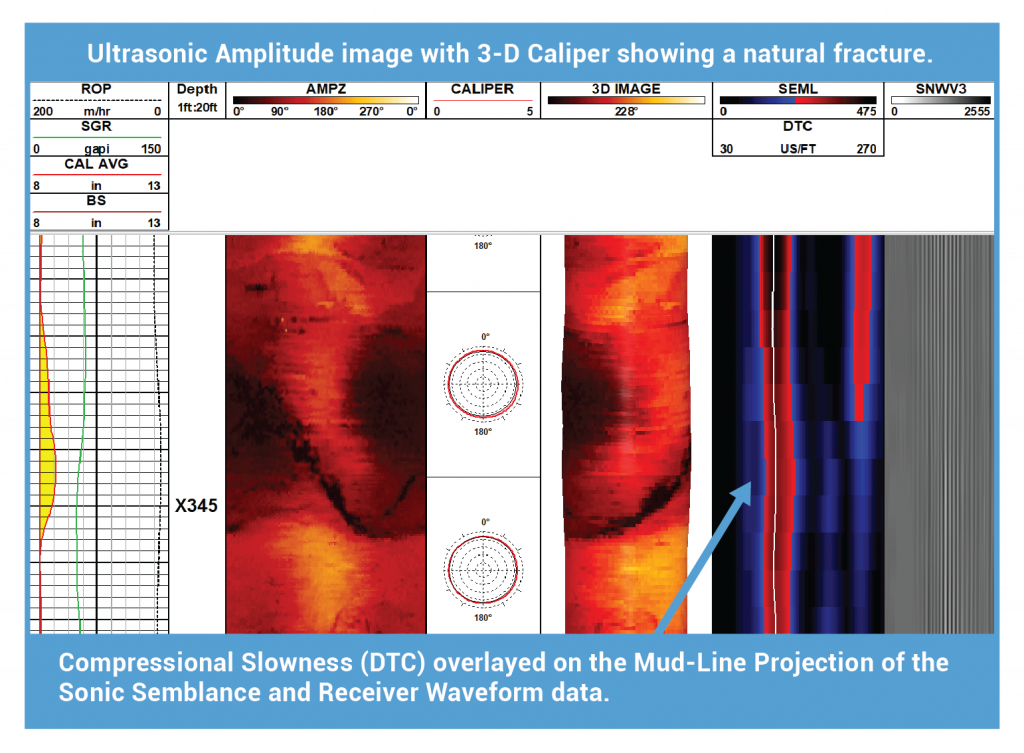

After the BHA was on the surface, memory logs from the ULT showed some natural fracturing in the formation above the well’s target zone. Subsequent wireline logs showed a good correlation between the LWD and wireline comparative measurements.

CLIENT VALUE

A rotary steerable system uses drilling the production section separately, resulting in bit-to-sensor distances for the sonic and resistivity packages at 56ft and 22ft. These high-quality measurements allowed well correlation, pay zone evaluation, and pore pressure prediction.

The accelerated turnaround time (<24 hours) of processing the memory data allowed informed decisions regarding which suite of logs to run via wireline. Due to the high confidence in the LWD data, the client made well-informed and intelligent decisions. In conclusion, the production section of 2,680ft drills in only 44 on-bottom hours.

YOU MAY ALSO BE INTERESTED IN

ULT Determines Fracture Communication Between Wells