Navigation

Relief Well Intercept with Active Magnetic Ranging

APPLICATION

/ Relief Well

/ Relief Well Planning

/ Well Control

/ Magnetic Ranging

/ Wellbore Surveying

TECHNOLOGY

/ BlackShark Active Ranging System

/ URSA gyroMWD

LOCATION

Onshore, US

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

Scientific Drilling’s approach to a relief well intercepted for the customer sought urgent relief to prevent a devastating blowout.

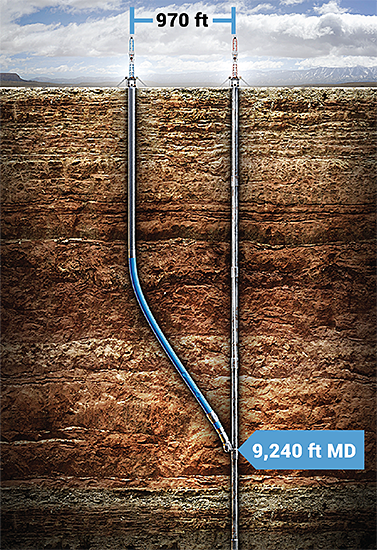

The primary purpose of the relief well intercept was to relieve pressure and provide a pathway to facilitate well control operations for the targeted well. For instance, during workover operations, extensive damage occurred to the 7-inch casing of the target well. Therefore, the damage prevented further workover attempts. As a result, concerns arose regarding the potential failure of a kill plug set in a 4.5-inch liner at 9240 ft/MD.

SCIENTIFIC SOLUTION

The intercept depth was above the 4.5-inch liner plug at 9240 ft measured depth. The well was spud 970 ft away from the targeted well on the surface.

Magnetic Ranging Technology: The use for the obstruction was Scientific Drilling’s BlackShark Active Magnetic Ranging. A current enters the formation, and the target well casing releases a magnetic field. Furthermore, this magnetic field detects Blackshark and is used to locate the well position.

Advanced Wellbore Surveying Technology: Scientific Drilling’s solid-state URSA gyroMWD system steers the well toward the target well. Therefore, the system mitigates magnetic interference challenges and ensures accuracy in the intercept.

Environmental and Safety Measures: Extreme cold weather created transportation hazards to and from the rig location. Therefore, health and safety procedures such as safe driving and journey management use. As a result, no recorded incidents or near misses occurred.

CUSTOMER VALUE

Accuracy and Precision of Magnetic Ranging: The BlackShark Active Magnetic Ranging System provided high-accuracy measurements of the target well position. Therefore, even at distances exceeding 200 ft center-to-center length. The BlackShark allowed an accurate intercept without the need for wellbore detours.

Efficient Operations: The intercept occurred 30 days from the spud date. The shorter drilling duration compared to typical relief wells demonstrated the efficiency of the solutions deployed.

Successful Intercept: The wells successfully intercept on the first attempt. Therefore, well showcased the effectiveness of the chosen technologies and techniques.

Best Practices: This project demonstrated that planning and drilling an intercept relief well in a short amount of time is possible. Proper planning, accurate Magnetic Ranging technology, and devotion to safety procedures contributed to the project’s success.

YOU MAY ALSO BE INTERESTED IN

Reservoir Performance and Tubing Evaluation in One Run