Navigation

Reservoir Performance and Tubing Evaluation in One Run

APPLICATION

/ Production Logging

/ Well Integrity

TECHNOLOGY

/ Cased Hole Services

/ Vulcan FLS 2.25

/ Vulcan MFT-24

LOCATION

/ North Sea

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

An Operator of an HPHT field in the North Sea sought to reduce the number of wells involved. In a one-well data acquisition campaign, minimize the non-productive time (NPT). However, a downhole temperature of 175°C limited the range of available technologies. For example, the limitations consisted of applying production logging tool (PLT) data and evaluating tubular of multiple sizes.

SCIENTIFIC SOLUTION

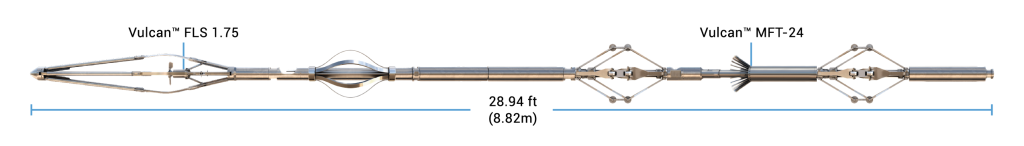

Scientific Drilling International’s (SDI) combined Vulcan™ MFT-24 and Vulcan™ FLS 1.75 (gamma-ray, casing collar locator, pressure, temperature, and spinner). The combination provides a unique tool-string arrangement to meet the Operator’s data goals.

For instance, the first part of the well intervention comprised PLT passes across the pierced interval. In addition, the well intervention followed the collection of high-resolution and high-sample rate (0.01 sec) multi-finger caliper data. Therefore results in three different tubular sizes on the data on the way out of a hole. Above all, both tools collected high-quality data.

CUSTOMER VALUE

The caliper and PLT data acquisition conducts in memory mode. Therefore, enabling the lower cost, lower risk choice of slickline transportation. Thus, combining the caliper with the PLT allowed the Operator to eliminate one run. The elimination of the run resulted in significant cost savings.

Despite the high temperature, SDI’s high-performance logging tools provided the Operator with excellent-quality data. Above all, helping the Operator to optimize the management of its well and reservoir.

YOU MAY ALSO BE INTERESTED IN

High-Quality PLT and MFT Data from Ultra Hot Gas Well