Navigation

High-Temperature Post-Frac Liner Evaluation

APPLICATION

/ Cased Hole Logging

/ Well Integrity

TECHNOLOGY

LOCATION

Australasia

DOWNLOAD CASE HISTORY

/ PDF File

CLIENT CHALLENGE

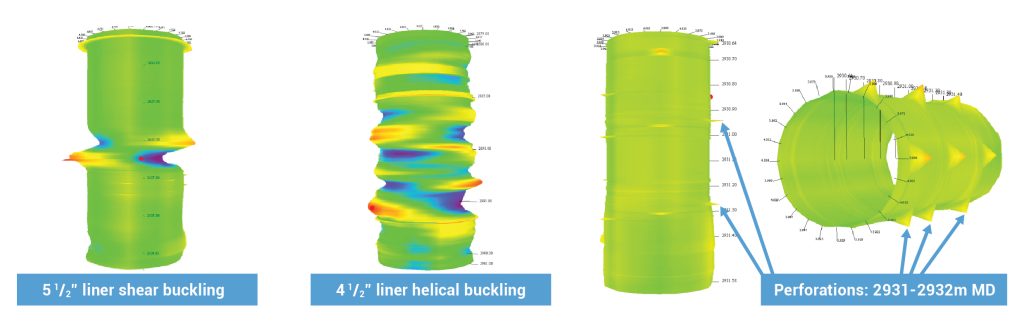

A client’s frac operations in two wells (one completed with 5 1/2″ liner and the other 4 1/2″) resulted in suspected liner deformation.

Therefore, with a maximum well temperature of 165°C (330˚F), standard logging tools would likely encounter problems.

The client’s objective was to attain accurate and comprehensive data. In addition to visuals of the deformation without jeopardizing the tool’s integrity due to exposure to high temperatures.

SCIENTIFIC SOLUTION

Scientific Drilling offered a fit-for-purpose solution with the Vulcan™ MFT-24 caliper. The Vulcan™ MFT-24’s pervasive track record in high-temperature applications gave clients confidence in meeting their data acquisition requirements.

A time-in-flask simulation was conducted before the run to inform the maximum possible run duration before reaching the tool’s maximum internal temperature. The simulation showed that logging could be performed across the interval of interest at 6m/min, equating to a vertical resolution of 0.036″, thanks to the fast-sampling rate of 100/sec.

CLIENT VALUE

Above all, in the Vulcan™ MFT-24, the client made no compromise on the quality and quantity of the data acquisition. The alternative option of deploying standard temperature tools would have likely resulted in lower resolution data, requiring logging conducts faster to limit high-temperate exposure. A standard tool may have significantly impaired the ability to capture the data quality needed to produce the 3D images in the figures.

In conclusion, data delivered by Scientific Drilling provided the client with the insight required to plan subsequent well interventions and remedial operations safely and efficiently.

YOU MAY ALSO BE INTERESTED IN

Relief Well Intercept with Active Magnetic Ranging