Navigation

Dual-Technology Approach to Leak Detection

APPLICATION

/ Well Integrity

TECHNOLOGY

/ Cased Hole Services

/ Vulcan™ MFT-24

/ Standard FLS

LOCATION

/ Asia Pacific

DOWNLOAD CASE HISTORY

/ PDF File

CLIENT CHALLENGE

Sustained annulus pressure (SAP) compromised an operator’s injector well. The source of SAP was suspected to be communication between the tubing and casing. Therefore, to help understand the issue, the operator consulted with Scientific Drilling. For instance, we are known as the premier memory-logging provider in the region. The data collection objectives were two-pronged. For example, to determine the location of the tubing leaks and evaluate the integrity of the tubing in the area of the leaks for tubing patch/straddle setting purposes.

SCIENTIFIC SOLUTION

Scientific Drilling advised a dual-technology approach. For example, we deployed a Memory PLT to assess the flow dynamics inside the tubing and a high-accuracy memory multi-finger caliper to attempt to identify 100% puncturing in the tubing wall.

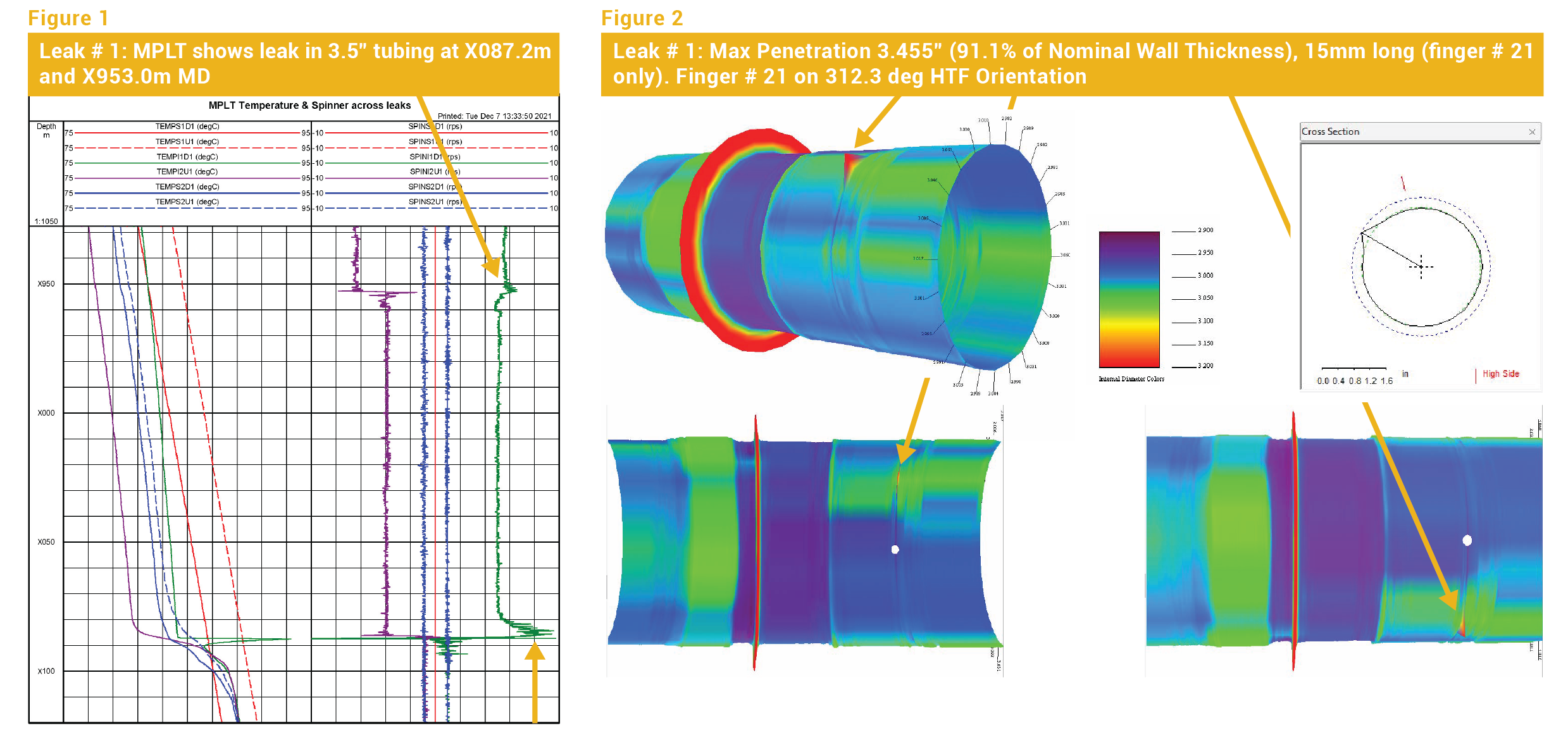

On the first run, the MPLT transports and log passes perform across the suspect area in shut-in and injection conditions. The data positively revealed leaks at X087.2m and X953.0m, as shown in Figure 1. On the next run, the Vulcan MFT-24 memory caliper ran to the bottom of the interval of interest, and data were collected at a frequency of 0.01 seconds while logging at a speed of 15/min, reducing velocity to 5m/min across the leaks identified by the MPLT data. As a result, the processed data showed that the caliper detected a maximum puncturing of 91.1% of nominal wall thickness at X087.2m and an irregularity of 26.6% at X953.0m (figure 2). These abnormalities are consistent with the MPLT leak detection results, as seen in the spinner and temperature data. When a caliper finger crosses a hole, it will not usually detect 100% maximum piercing. Therefore, this would require the finger to cross over the hole’s center and for the hole’s size to be large enough for the full pivot of the finger to enter it. Meanwhile, the maximum puncturing at X087.2m and X953.0m MD is less than 100%. They can still be holes because of this occurrence.

client VALUE

The customer received a clear answer to their compromised well integrity issue efficiently and cost-effectively thanks to Scientific Drilling’s memory logging expertise, proprietary technologies, and highly responsive log analysis service.

YOU MAY ALSO BE INTERESTED IN

Radical Deployment of Multi-Finger Caliper

Radical Deployment of Multi-Finger Caliper