Navigation

Radical Deployment of Multi-Finger Caliper

APPLICATION

/ Well Integrity

/ SAGD

TECHNOLOGY

/ Cased Hole Services

/ Vulcan™ MFT-24

LOCATION

/ North America

DOWNLOAD CASE HISTORY

/ PDF File

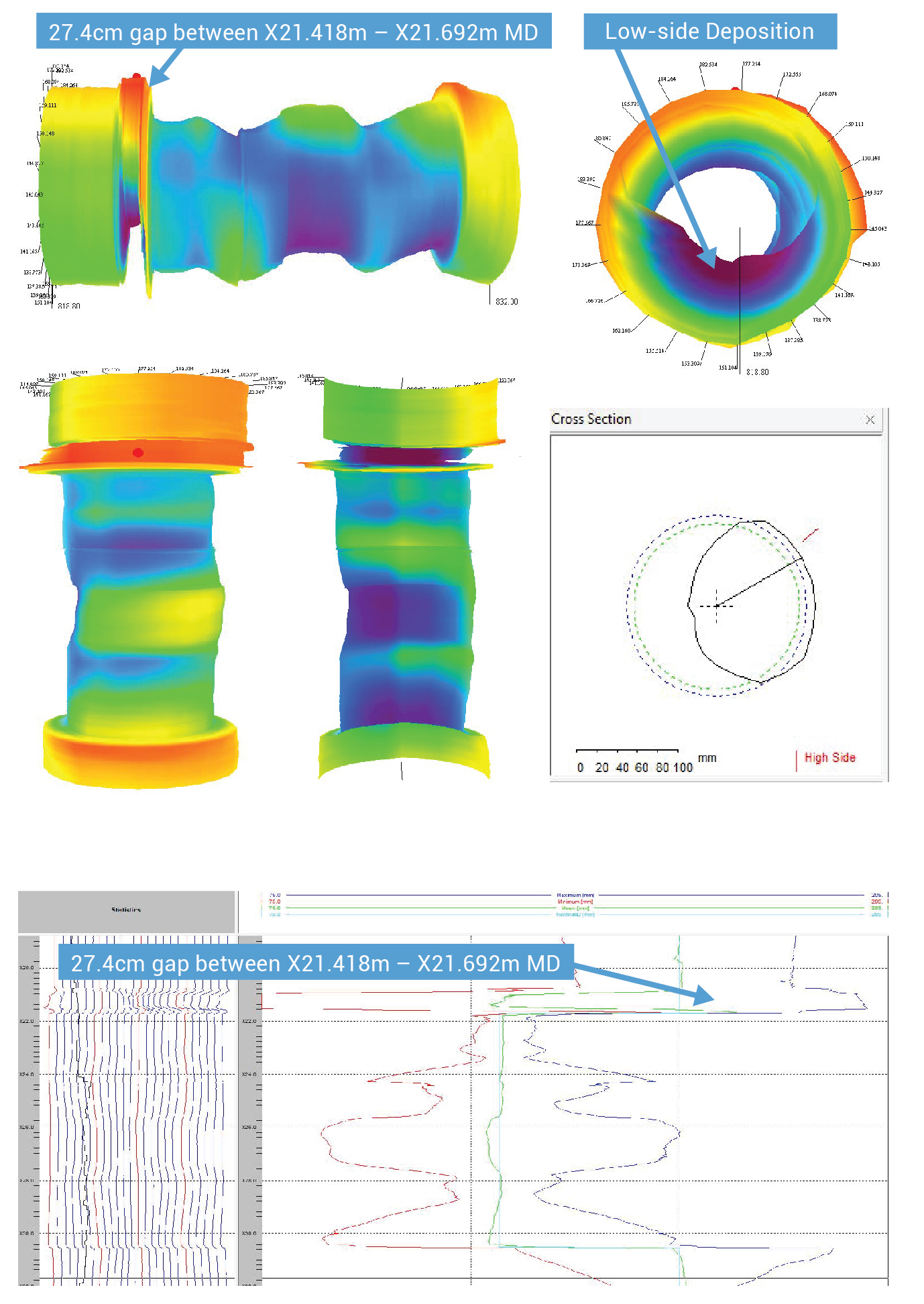

CLIENT CHALLENGE

The steam-assisted gravity drainage (SAGD) field operator wished to devise a method of deploying a multi-finger caliper (MFC) in the lateral section of its well. As a result, without resorting to coiled tubing (CT) or wireline tractor to reach the target depth. A workover rig with drill-pipe conveyance was the favored solution. Therefore, the objective of the MFC survey was to identify gaps in the top and bottom connection of cross-overs in the 7″ x 5.5″ liner screens and to evaluate the condition of the limited entry perforations (LEP).

SCIENTIFIC SOLUTION

The challenge of reaching the desired depth in the lateral would require a unique distribution. In close collaboration with the client, the determination that a pump-down mode of tool transportation would be the optimal solution. Meanwhile, an appropriate tool-string arrangement was designed to enable it to be dropped inside the drill pipe and pumped down while minimizing the shock of the impact.

The memory Vulcan MFT-24 caliper fingers programs at a 0.02-second sample rate (50 samples per second) for the entire duration of the operation. The fingers were programmed to open at the bottom of the logging interval and to close at the surface after logging. The Vulcan MFT-24 was dropped inside the drill pipe and pumped down to exit into the liner at approx X597m MD (top of tool latched securely at the end of the drill pipe). When the Vulcan MFT-24 fingers opened to schedule, pulling the tool string out of the hole at approx—10 m/min. The fingers closed before reaching the surface at approx X95m MD.

For instance, uploaded at the surface was the data, and the quality was checked. All fingers provided data for analysis.

client VALUE

The elimination of coiled tubing and wireline tractor saved the client tens of thousands of dollars. All job objectives were met and several gaps were identified, including a maximum of 27.4cm.

YOU MAY ALSO BE INTERESTED IN

Parted Tubing in SAGD Well Captured in 3D Images

Parted Tubing in SAGD Well Captured in 3D Images