Navigation

One Attempt Well Intersect with Lodestone

APPLICATION

/ Well Intercept

/ Magnetic Ranging

/ Unconventional – Coal Bed Methane

TECHNOLOGY

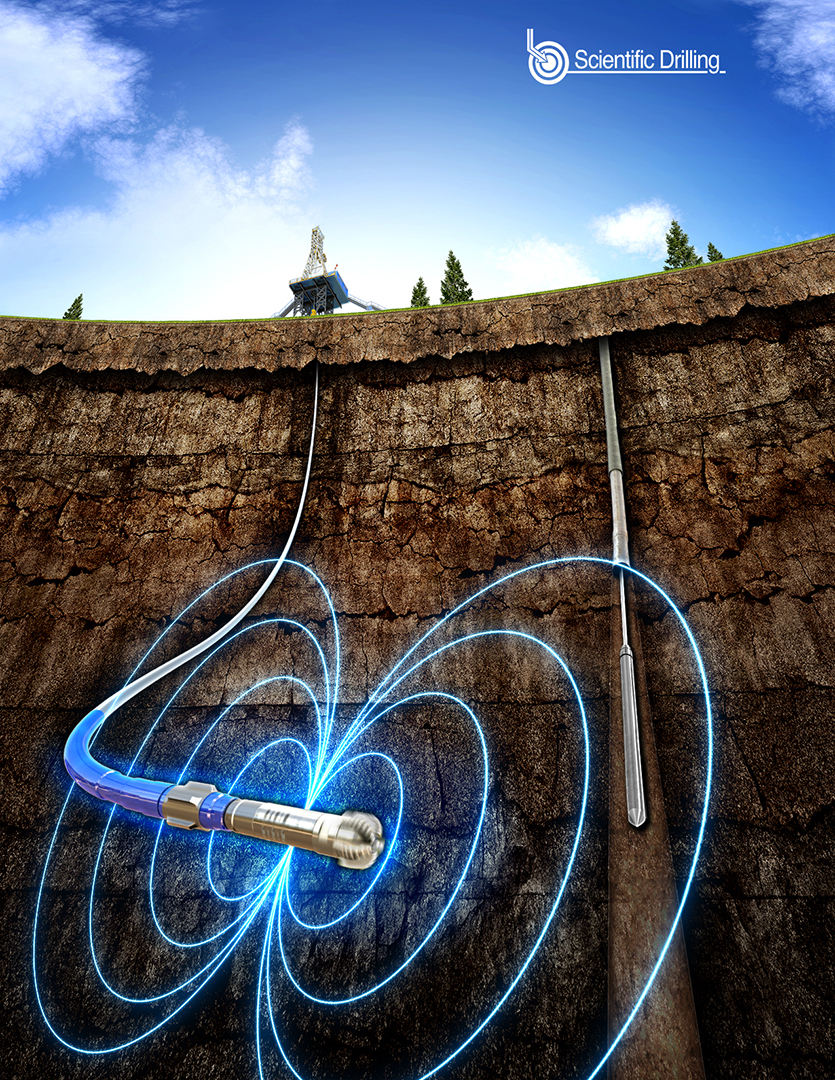

/ Lodestone Active Ranging

/ Keeper gyro

LOCATION

Poland, Continental Europe

DOWNLOAD CASE HISTORY

/ PDF File

CUSTOMER CHALLENGE

To extract gas from the CBM producer well, the client needed to drill an additional horizontal wellbore. For instance, the wellbore intersects a single joint of pre-set fiberglass casing at 1055m MD and 45° of inclination.

Using Gyro and MWD survey methods alone could not provide enough accuracy to allow for a first-time intersection. These traditional methods effectively mean that the operator is drilling blind. Therefore, it required multiple sidetracks. For example, until intercepted successfully, if at all. This results in extended rig time and inflated project costs.

SCIENTIFIC SOLUTION

SDI’s Lodestone at bit ranging was positioned for the horizontal drilling well to guarantee an obstruction on the first attempt. For instance, the Lodestone sonde was placed via wireline in the single joint of the fiberglass casing of the existing well at a depth of 1054.9m MD.

After the drill out, the signal obtains 1027.0m MD (drilled well), ranging data collection at 1146.01m and 1.27m from the intercept point. The sonde tripped out of the hole, and the target well intercepted at 1147.71m MD.

Above all, utilizing a 24/7 operation with seamless integration. Scientific Drilling International Active Ranging, Directional Drilling, and Well Planning services are provided both on-location and remotely from real-time data centers in the UK and Houston. Furthermore, SDI provides new target positioning data instantly generated after each ranging sample.

The ability to range from an unprecedented 120m away ensured that the target well was consistently monitored. For instance, from the start of the 6″ hole section, guaranteeing a successful one-attempt intersect of the offset well.

CUSTOMER VALUE

SDI intersected the offset well on the first attempt, saving the client days of additional rig time. Thanks to SDI’s Lodestone at bit ranging solution. The potential for fly-pasts and concerns for wellbore stability eliminates.

YOU MAY ALSO BE INTERESTED IN

Dual-Technology Approach to Leak Detection

Dual-Technology Approach to Leak Detection