Navigation

ULT IMAGES FRACTURE ORIENTATIONS ADJACENT TO FAULT IN PERMIAN BASIN LATERAL

APPLICATION

/ Reservoir Modeling

/ Completion Optimization

/ Geosteering

TECHNOLOGY

/ Unconventional Logging Tool (ULT)

LOCATION

Midland Basin, Wolfcamp Shale, TX

DOWNLOAD CASE HISTORY

/ PDF File

CLIENT CHALLENGE

In order to better understand the production variations along their Wolfcamp shale laterals, an operator needed additional information regarding the stress state differences when drilling across geologic structures, such as faults.

The operator did not wish to spend the additional time running drill pipe-deployed wireline tools for the entire lateral section and were running oil-based mud, limiting the selection of LWD sensors capable of acquiring the high-resolution image data required.

SCIENTIFIC SOLUTION

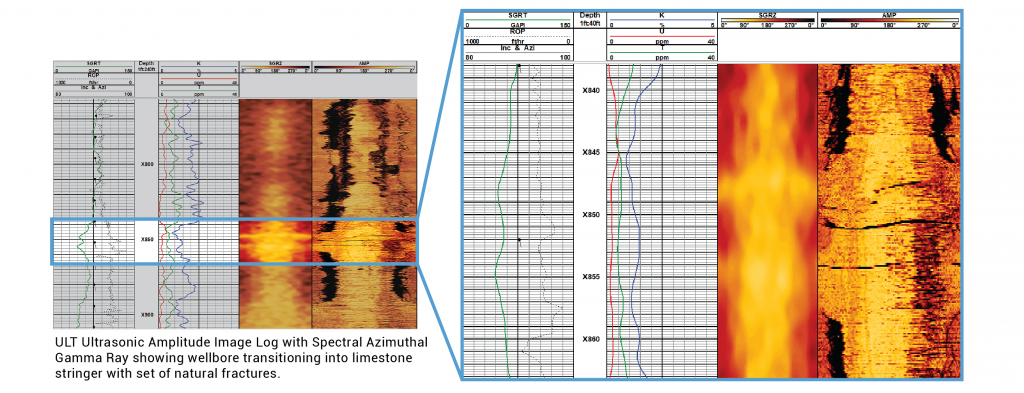

Scientific Drilling deployed its Unconventional Logging Tool (ULT) in the drilling BHA behind a motorized rotary steerable system. The 128-sector ultrasonic images recorded natural and induced fracture orientation changes near a seismic-interpreted fault system located halfway through the lateral. In addition, the borehole caliper also recorded numerous intervals of borehole breakout when drilling across weak bedding planes in the target’s clay-rich layers of the shale formation.

CLIENT VALUE

The ULT’s high-resolution ultrasonic image data recorded to memory provided the client with the stress field rotation from the induced fractures recorded near the fault.

Since the ULT was run in the drilling BHA, no additional time was spent logging with wireline tools after reaching TD. Additionally, the normal drilling ROP was not affected while running the LWD tool.

YOU MAY ALSO BE INTERESTED IN

Time-Lapse ULT Caliper Log Measures Borehole Breakout